Swan's Three-Thread Intelligent Vision Machine | Smart Cleaner, Quality Guardian

For more than twenty years of active development, China's cotton industry has gone through a path of rapid growth. Today, China accounts for about 1/4 of the world's cotton production, as well as 1/3 of the world's consumption and export of textile and clothing products. From cotton cultivation to the export of textiles and clothing, the country has formed a large-scale and fully developed production chain. As a key force in global cotton production and consumption, China has long determined not only the quantitative indicators, but also the direction of development of the entire global industry.

However, the cooling of the global economy is gradually affecting the industry: exports of textiles and clothing are facing difficulties, enterprises are losing orders, and domestic effective demand is weakening. China's cotton industry is experiencing unprecedented growing pains. But the harsher the frost, the more resilient is demonstrated: the efforts of all links in the chain are united, and technological innovation, active market development and a commitment to sustainable development form a clear path out of the crisis.

Technological code of cotton fields

AI three-thread machine and contract farming form a closed quality loop

The seeds are the “chip” of the cotton industry. The genetic code of each seed contains prospects for growth in yield and fiber quality, and therefore the foundation for the development of the entire industry. In Hejian City, Hebei Province, the Guoxin Agricultural Technical Services Association has been proving the value of “good seed” for more than 40 years. An intellectual base for crop selection and management has been created on our own seed farms with an area of over 70 thousand mu in the Bayangguolin Mongolian Autonomous Region of Xinjiang.

The 36 officially approved cotton varieties provide farmers with reliable seed material, stably supply the Xinjiang market, and make “Chinese seed kernel” synonymous with quality in the region's cotton industry.

The effect of improved quality is especially clear in Xinjiang's cotton fields. In 2024, the share of high-quality cotton in the region exceeded 50%, and the logic of “good cotton - good yarn” closed the chain from the field to the production floor.

As a world leader in colored yarn, Huafu Fashion deeply understands this. Founded in 2018, Cotton Art has implemented an enterprise + farmers + cooperatives model, supplying quality seeds and technology directly to the fields and purchasing compliant cotton at a guaranteed price. At the processing stage, Huafu adapts its processes to key parameters such as micronaire, allowing each batch of cotton to reveal its optimal properties.

If selection is the starting point of quality, then innovation in processing becomes its reliable guardian. The AI three-thread machine developed by Shandong Swan Cotton Machinery is rightfully considered the “smart cleaner” of the cotton processing unit. High-precision machine vision and sophisticated algorithms accurately detect and remove foreign fibers, keeping impurities to a minimum. In combination with subsequent equipment for removing foreign fibers at the spinning stage, a “double barrier” is formed, providing reliable technological protection for the production of high-quality white yarn.

As technological innovation becomes the general industry consensus, Chinese cotton makes the transition from “scale advantage” to “quality advantage”.

Innovative scenarios for using cotton

To ensure that consumers wear “breathable sun protection clothing”

Changes in the consumer market are often more revolutionary than transformations in production. Demands are shifting from "yes or no" and "good or bad" to "eco-friendly and personalized," from basic functions to adaptation to specific scenarios. Exploration of new frontiers for cotton has already begun, and the growth of the PurCotton (All Cotton Era) brand is a clear example of this.

Thanks to a breakthrough in cotton spunlace technology, the company effectively created a new market: first, cotton wipes with soft and eco-friendly properties transformed the paper goods market, and then the technology spread to wet wipes, baby products, and feminine hygiene.

A real hit of 2024 has been pure cotton sun-protective clothing, which has taken design innovation to a new level.

"We use textile technologies to imbue cotton with UV protection, antibacterial, and cooling properties, appealing to consumers with the concept of 'breathable sun protection clothing,'" noted Liu Hua, Vice President of Shenzhen PurCotton Technology Co., Ltd. As cotton expands beyond home textiles and basic clothing, emerging sectors such as outdoor clothing are emerging as promising growth markets.

The revolution in distribution channels has further reduced the distance between quality cotton products and consumers. The Tenbro brand of the Esquel group, having adopted the experience of working with the world's leading brands, has successfully entered the domestic market through e-commerce and livestream sales. In live broadcasts, presenters not only explain fabric technology in detail, but also demonstrate products in comparison, allowing consumers to clearly assess the value of the product. As a result, the share of online sales quickly grew to 70%. At the same time, premium offline stores in the central areas of megacities create an immersive consumer experience. The merging of online and offline channels is reinventing the cotton consumer chain.

Implementation of sustainable development

Each cotton flower received a “green passport”

With a green and low-carbon economy becoming a global consensus, sustainable development has become the entry ticket for the cotton industry to compete internationally.

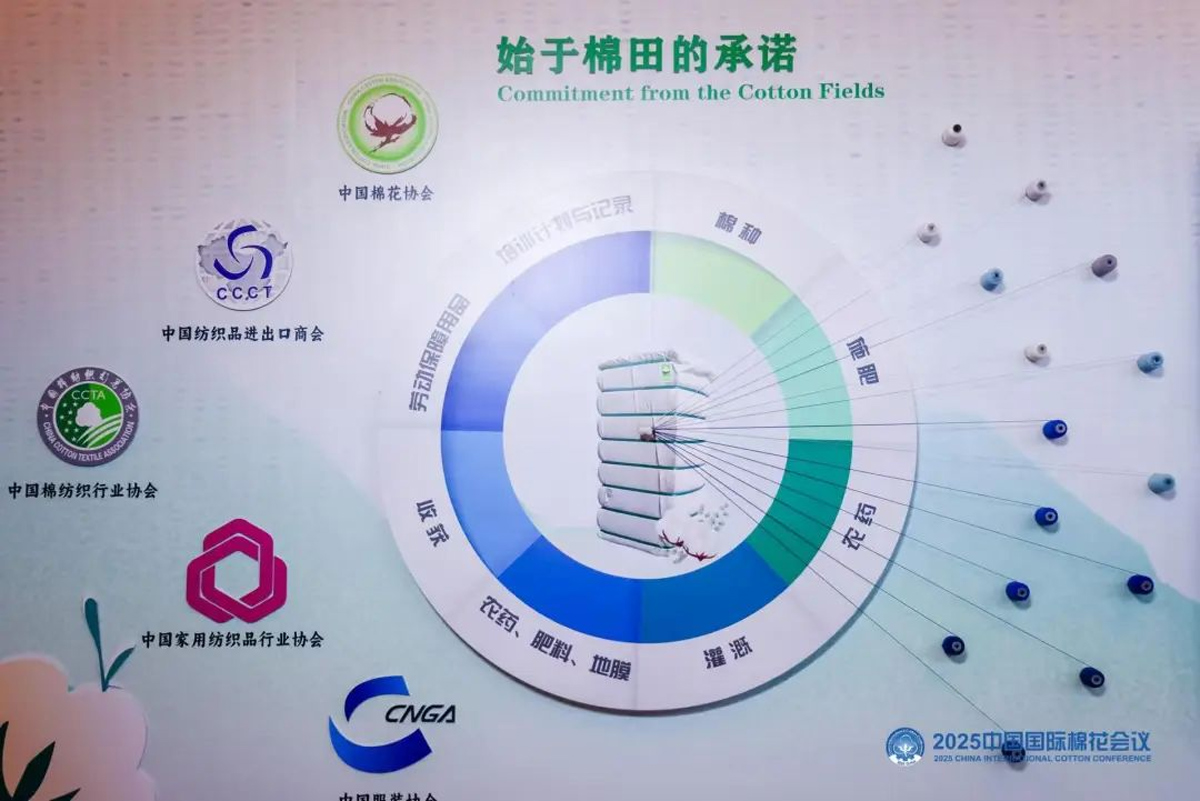

In 2021, the China Cotton Association, together with four textile associations, launched the China Cotton Sustainability Project, based on the principles of environmental friendliness, respect for labor, high quality, and full traceability. An independent and verifiable certification standard was created, covering the entire supply chain—from field to shelf:

At the production stage, farmers are guided to use environmentally friendly technologies, and third parties exercise full control;

In the supply chain, the traceability system transfers the responsibility of the cotton fields to each link;

At the consumer stage, certified products are labeled, increasing consumer confidence and creating additional value for the business.

Six Farms Xinjiang Lihua (Group) Co., Ltd. As a case in point, drip irrigation saves more than 40% of water compared to traditional methods, and green technologies reduce chemical pollution so that every cotton flower carries an eco-label. Esquel's Tenbro brand was one of the first to launch sustainable labels and plans to extend the label to all products containing more than 85% cotton.

Over several years of operation, the Chinese Cotton Sustainable Development Project has united about 40 enterprises in the industry chain and certified 1.2 million mu of cotton fields in Xinjiang. A sustainable ecosystem began to emerge, covering cultivation, processing and branding. In the future, the China Cotton Association plans to further improve standards and accelerate the formation of a portfolio of national brands. As sustainability moves from concept to actual competitiveness, Chinese cotton finds a new foothold in the global value chain.

From technological breakthroughs to market expansion, from standard setting to ecosystem development, the Chinese cotton industry's path out of crisis is not only a response to current challenges, but also a path to future renewal. Along the way, every innovation rewrites the industry's genetic code, and every breakthrough changes global perception. This may be the most moving story of Chinese cotton.

(Source: China Cotton Association)

- In the previous : На основе хлопкоочистительно...

- The next article : Heavy equipment of a great power that laid the foundations of the country's might. The Swan cotton picker is on display at the National Museum of China at the exhibition "Achievements of Chinese Manufacturing during the 14th Five-Year Plan Period."