Ribs for a raw cotton cleaning machine

1. Professional conveyor production ensures high precision, excellent uniformity, and guaranteed consistent gaps. The operating point has a linearity 1.5 times higher than the state standard, reducing defects in raw cotton processing.

2. Adopting professional chrome plating and working point hardening technology ensures high surface hardness and long service life.

3. Original production ensures ease of assembly with basic equipment, helps reduce the number of NEP nodes and ensures high quality processing.

4. Each saw set is assembled, tested and numbered before shipping, which ensures ease of installation and convenient adjustment.

1. Product description

The saw set (cotton gin ribs) is a key component of the cotton ginning machine (gin). It is mounted on the machine's rollers to transmit power and ensure the separation of the cotton fiber from the seeds. Typically, saw sets for gins are made of high-strength alloy steel and offer strength, durability, wear resistance, and high reliability.

2. Technical specifications

(1) Application: Spare parts for fiber separation machines (gins)

(2) Material: Alloy steel

(3) Country of origin: China

(4) Surface hardness: 55 HRC

3. Packaging and delivery

(1) The transportation mode is flexible and can be changed; different transportation modes can be adopted according to customer's needs.

(2) The packaging materials are strong and durable, which can adapt to long-distance international transportation.

(3) Customer-oriented, customizable packaging.

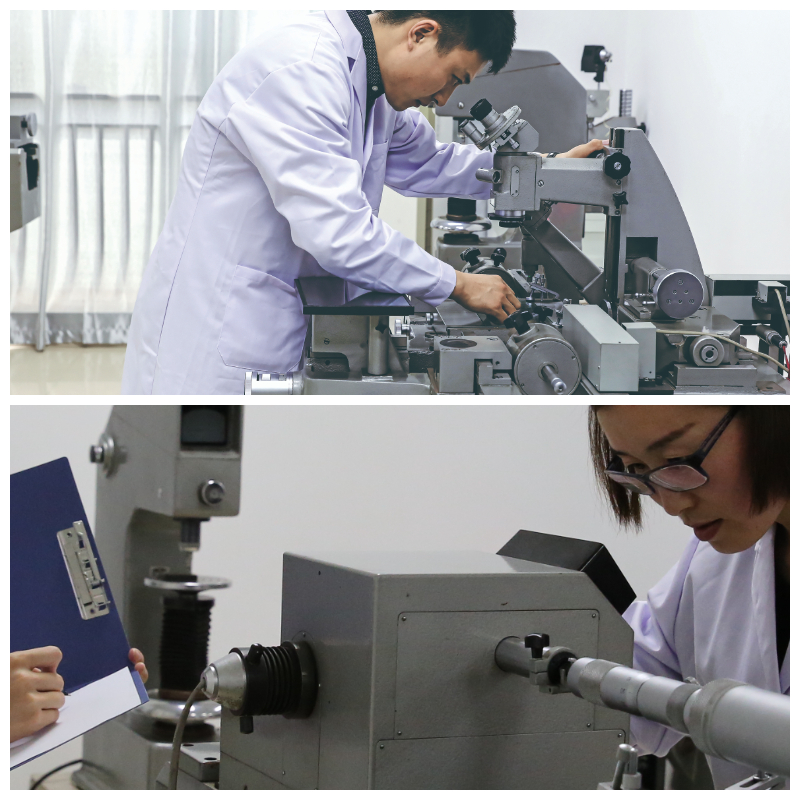

4. Quality control

We conduct rigorous comprehensive testing on every unit of product leaving the factory, which primarily includes the following:

(1) External inspection: Checking whether the product's appearance meets the requirements, including color, shape, size, surface cleanliness, etc. This can be done by visual inspection or by using auxiliary instruments (e.g. microscopes, measuring instruments).

(2) Functional testing: Verifying that the product's functions operate correctly. This can be done by operating the product, conducting functional tests, or using specialized test equipment to check the product's performance and functionality.

(3) Safety Testing: Verifying that the product complies with relevant safety standards and regulatory requirements. This may include electrical, mechanical, chemical safety testing, etc.

(4) Packaging Inspection: Checking the integrity of the product packaging, the clarity of the markings, and the compliance of the packaging materials with the requirements. This ensures that the product will not be damaged during transportation and storage and can be correctly identified.