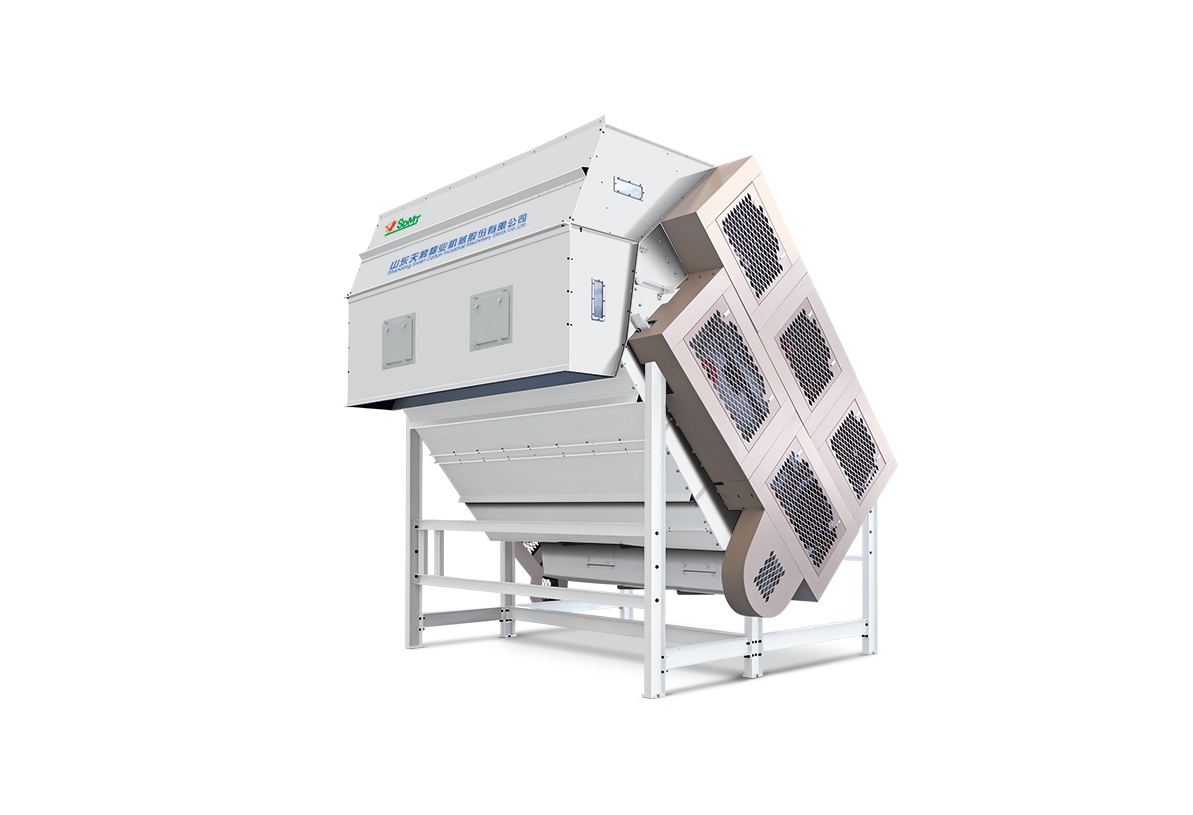

cotton seed cleaning machine

1. The machine consists of upper and lower parts, which work as a single unit or independently.

2. Multifunctionality – reduces installation height, saves space and reduces equipment and installation costs.

3. Independent design of parts - higher cleaning efficiency and less fiber loss.

4. Spiked drum - patented 14-sided design: stable, minimal vibration, cleaning efficiency ≥65%.

5. Spikes - CNC machined, conical shape with rounded head: less damage and clogging.

6. Removable casing - phosphating + powder coating: excellent adhesion, corrosion and oxidation resistant, aesthetically pleasing.

Product Introduction

The two-tier hierarchical seed cotton ginner is an equipment used in the cotton industry to remove impurities from raw cotton and seed cotton. This equipment is characterized by high cleaning efficiency and ease of operation. It simultaneously improves the quality and purity of cotton, reduces the labor intensity and cost of manual cleaning, and increases productivity.

Scope of application

The main purpose is to clean machine-picked cotton, hand-picked cotton, and regular hand-picked cotton.

Specifications

| Model | Capacity (kg/h) | Power (kW) | Overall dimensions (L×W×H), mm | Weight (kg) |

MQZF-15 |

13 000 ~ 15 000 |

44 |

4310 × 4222 × 4247 |

13 000 |

MQZF-12 |

10 000 ~ 12 000 |

37 |

3860 × 4222 × 4247 |

12 000 |

MQZF-10 |

8 000 ~ 10 000 |

30 |

3100 × 4177 × 4247 |

11 500 |

Note: The stated productivity refers to standard seed cotton with a moisture content of no more than 7%, which, after processing, produces fiber that meets the established quality requirements.

Packaging and delivery

Each vehicle is securely fastened and reinforced within the container to ensure safe delivery to the destination port.

The entire process of loading equipment and sealing the container is documented by photo and video recording; the entire process is transparent and controlled.

The company partners with reliable shipping companies; key delivery stages are updated in real time.

Acceptance of products

External inspection: checking the conformity of the product's appearance with established requirements, including color, shape, surface quality, etc. Inspection can be carried out visually or using auxiliary instruments (e.g. microscopes, measuring instruments).

Functional testing: checking the correct operation of all product functions. This is done by running the equipment, performing functional tests, or using specialized test equipment to confirm the performance and functionality of the product.

Safety verification: assessing the product's compliance with current safety standards and regulations. This may include electrical, mechanical, chemical, and other safety checks.

Packaging inspection: checking the integrity of the packaging, the clarity of the markings, and the compliance of the packaging materials with requirements. This ensures the safety of the product during transportation and storage, as well as the correct identification of the product.

Company information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a public joint-stock enterprise belonging to the supply and marketing cooperative system of Shandong Province. The company's origins date back to 1946. Currently, the company combines R&D, precision manufacturing, marketing support and capital management, providing comprehensive solutions and a full range of service for mechanized, intelligent and digital cotton processing equipment. The company's products are exported to more than 30 countries, and its share in the domestic market has maintained a leading position for many years. An extensive service and marketing network covers the world's major cotton growing regions.

The main activity of the company is the production of cotton ginning equipment, which allows it to actively contribute to the modernization and digital transformation of the industry, introduce a new generation of “smart” production and build a reputation as a leading global brand in the field of cotton machinery. At the same time, Shandong Swan is expanding its presence in the segment of intelligent agricultural equipment and is consistently developing the direction of high-tech equipment.

The company has four technical centers and production sites in Jinan (Shandong Province), Wujiaqu (Xinjiang), Hailar (Inner Mongolia) and Montgomery (USA), and also includes three national high-tech enterprises and six provincial innovation platforms. For many years, the company has taken a leading position in the technological development of the industry, has the status of a high-tech enterprise in Shandong Province, is a technical partner of the National Program for the Introduction of Scientific and Technological Achievements, and implements projects within the framework of the Fifteen-Year Plan under national priority research and development programs.