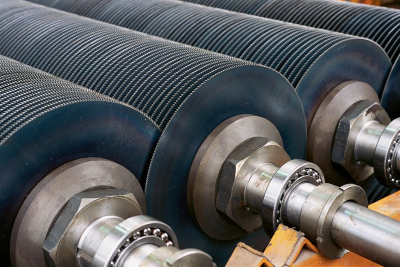

Cleaning drum with spikes for cotton processing machine

Made of high quality special steel to ensure long service life.

The teeth in the upper part are hardened and ground, and have high wear resistance and increased resistance to lodging.

Manufactured on a professional assembly line, the precise shape ensures a tight fit of the saw blade to the round shaft.

Adopts advanced international laser processing technology, ensuring high precision and no deviation.

Specifications

(1). Country of Origin: China

for effective removal of impurities from raw cotton during its processing. Thanks to optimally located spikes, the drum provides an intense but gentle effect on the cotton mass, effectively separating plant debris, dust and other foreign matter without damaging the fiber.

The product is made of high-strength wear-resistant materials, which guarantees stable operation, long service life and reliability under continuous operation conditions. The drum design is highly balanced, low vibration and easy to maintain, which improves the overall performance of cotton processing equipment and improves the quality of cleaned cotton fiber.

Packaging and delivery

(1) The transportation method is flexible and can be varied; different modes of transportation can be adopted according to customer's requirements.

(2) The packaging materials are strong and durable, suitable for international long-distance transportation.

(3) Customer-oriented - packaging can be custom-made.

Acceptance control of products

For every unit of product leaving the factory, we conduct rigorous comprehensive testing, which primarily includes the following points:

(1). External inspection: checking whether the product's appearance meets the established requirements, including color, shape, size, surface quality, etc. Inspection can be carried out visually or using auxiliary instruments (e.g. microscopes, measuring instruments).

(2). Functional testing: Verifying the correct operation of a product's functions. This can be accomplished by operating the product, conducting functional tests, or using specialized test equipment to confirm the product's performance and functionality.

(3) Safety testing: Verifying that the product complies with applicable safety standards and regulatory requirements. This may include testing for electrical safety, mechanical safety, chemical safety, and more.

(4) Packaging inspection: checking the integrity of the packaging, the clarity of the labeling, and the compliance of the packaging materials with established requirements. This ensures that the product will not be damaged during transportation and storage and will be correctly identified.