Equipment for cleaning raw cotton

New type of cotton feeding: effective removal of debris, uniform advancement without dust.

Improved working box parameters: optimal roller movement, free adjustment of debris removal.

Intelligent control with safety ≥98%.

Seed discharge through the middle chamber: high productivity, low energy consumption, adaptability to wet cotton.

Imported saw blades (USA) – high performance, long service life, high-quality cleaning.

Scientific and rational design: stable operation, easy maintenance.

Streamlined protective housing ensures safety and environmental friendliness.

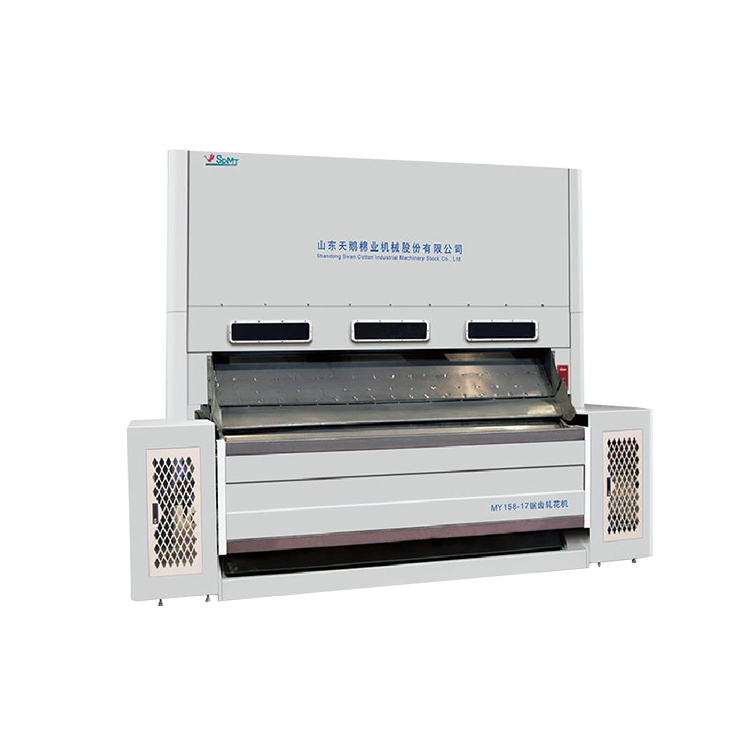

? Saw Gin for Cotton MY158-17

Product Introduction

Cotton sawing gin model MY158-17 is specially designed for separating fiber from cotton seeds and cleaning cotton seeds. It is equipped with high-quality imported components, and its design concept meets international leading standards. The processed fiber (lint) is of superior quality, low impurity content, excellent shape and has high market competitiveness, thereby creating higher economic value for our customers.

⚙️ Technical Specifications

Parameter |

Model |

Model |

MY158-17 |

Designed output |

1100-1800 kg/h |

Equipped power |

64.75 kW |

Lint ginning quality |

Meets or exceeds the national standard for ginned cotton |

Noise level |

90 dB |

Number of saw blades (Pieces of saws) |

158 pcs. |

Diameter of saw blades |

406 mm |

Saw spacing |

17 mm |

Diameter of brush cylinder |

380 mm |

Overall dimensions (W*D*H) |

$138 * 4068 * 3508.5 mm |

Machine weight |

8100 kg |

? Packaging and Delivery

We support individual (customized) packaging method for customers.

(1) Each machine is securely fixed and reinforced in the container to ensure safe delivery to the destination port.

(2) The entire process of product loading and container sealing is recorded by photo or video, making the entire process visible and controllable.

(3). Cooperation with a reliable shipping company, key time points (stages) are updated in real time.

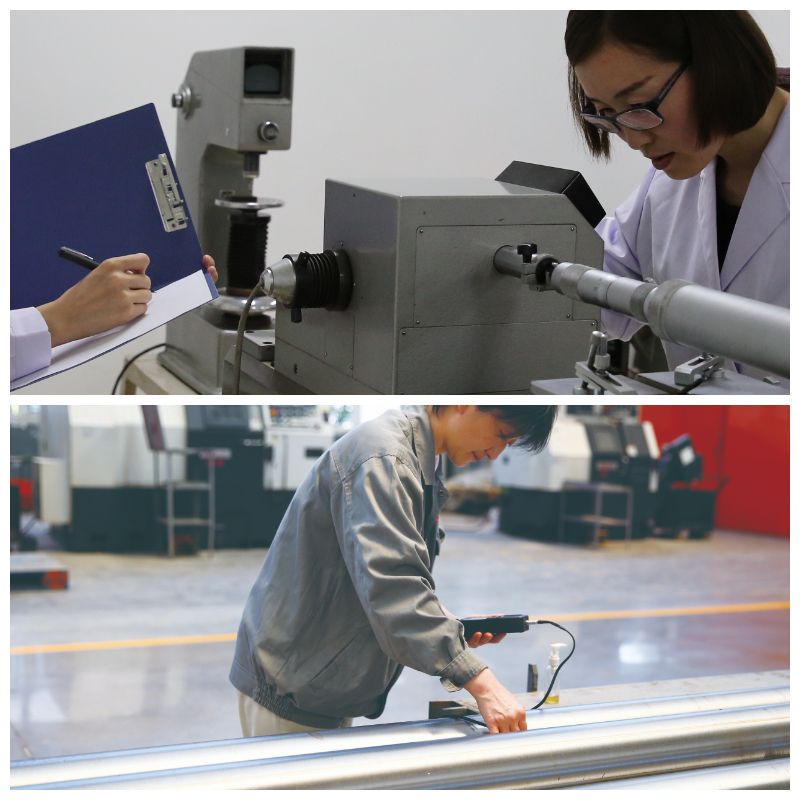

? Product Inspection

Each factory product undergoes rigorous comprehensive testing, which includes:

(1). Appearance inspection:

Checking whether the product's appearance meets requirements, including color, shape, size, surface cleanliness, etc.

(2). Functional Testing:

Verifying the correct operation of a product function through operation, functional tests, or the use of special equipment.

(3). Safety testing:

Verification of product compliance with relevant safety standards and regulatory requirements.

(4). Packaging inspection:

Checking the integrity of the packaging, clarity of markings and compliance of packaging materials with requirements.

? Company Information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a joint stock company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. The company integrates research and development, precision manufacturing, marketing services and capital management, and specializes in providing comprehensive services and supplies for mechanized, intelligent and computerized cotton processing equipment. Products are exported to more than 30 countries. The company has maintained a leading position in the domestic market for several years, and its marketing service network extends to all major cotton-producing regions of the world.

The company is focused on promoting the transformation and upgrading of the cotton industry, creating a new era of smart factories, forming the world's leading cotton machinery brand, actively expanding into the intelligent agricultural machinery industry, and fully entering the high-tech equipment manufacturing industry.

The company has four technical centers and production bases in Jinan (Shandong), Wujiaqu (Xinjiang), Hailar (Inner Mongolia) and Montgomery (USA), as well as three national high-tech enterprises and six provincial innovation platforms, leading the industry's technological progress. It is a high-tech enterprise in Shandong Province, the technical support unit of the "National Key Program for the Promotion of Scientific and Technological Achievement" and the implementer of the "13th Five-Year Plan" of the National Key Research and Development Program.

❓ Frequently Asked Questions (FAQ)

1. Q: Are you a factory or trading company?

A: We are a factory and have 4 of our own production bases in Jinan headquarters, as well as in Xinjiang, Inner Mongolia and Montgomery (USA).

2. Q: Where is your headquarters? How can I visit it?

A: Our headquarters are located in Jinan, Shandong Province, China. It's about a two-hour flight from Guangzhou or an hour and a half by high-speed train from Beijing. We look forward to welcoming you warmly.

3. Q: How does your factory carry out quality control?

A: Swan is the first company in the domestic industry to pass the ISO9001 quality system authentication and obtain three international quality assurance system approval certificates: CNACR, RAB, RVA (China, USA, Holland) and multilateral recognition in 20 countries around the world.

4. Q: What is your payment terms?

A: Negotiable. Telegraphic transfer (T/T) in advance or irrevocable letter of credit (IRRREVOCABLE LC).

5. Q: What is your order lead time?

A: Within 20-50 days after receiving the deposit or original L/C. If you have other questions or needs, please contact us, we will reply to you as soon as possible.