Raw cotton processing machine

The feeding and cleaning system ensures high efficiency, uniform cotton fall and no dust.

New working chamber parameters facilitate optimal roller movement and control of the long fibre content in the seeds.

The servo motor and PLC automatically adjust the camera parameters, improving the fiber quality and equipment efficiency.

The touch panel provides a convenient human-machine interface and ease of operation.

The rotating middle box removes stem residues, prevents roller stoppages and increases productivity in machine cotton.

Two pushers ensure stable and reliable opening/closing of the chamber.

The streamlined protective cover combines safety, environmental friendliness and aesthetic appearance.

Rational design and intelligent control ensure a high level of safety and ease of maintenance.

Product Introduction

The MYZ215-14.8 cotton gin is specially designed to meet the production needs of large and super-large cotton ginning enterprises.

The productivity of this model reaches 2-3 tons per hour.

The machine is equipped with a new extraction-type cotton feeding system and an improved design of the working chamber with optimized parameters.

The overall design of the equipment is scientifically sound and rational, ensuring stable, efficient and versatile operation, as well as adaptation to the processing of cotton of various origins and qualities in different regions of the world.

Specifications

Parameter

Meaning

Design capacity (kg/h) |

2000–3000 |

Installed capacity (kW) |

108.8 |

Number of saws (pcs.) |

215 |

Distance between saws (mm) |

14.8 |

Saw diameter (mm) |

406 |

Brush cylinder diameter (mm) |

450 |

Overall dimensions (L×W×H, mm) |

4720×3688×3558.5 |

Size of the inlet for raw cotton (L×W, mm) |

3328×320 |

Fiber outlet size (L×W, mm) |

3310×120 |

Machine weight (kg) |

12000 |

Packaging and delivery

Each machine is securely secured and reinforced inside the container to ensure safe delivery to its destination port.

The entire process of loading and sealing the container is recorded by photo or video, making it transparent and fully controllable.

The company partners with reliable shipping operators, providing up-to-date updates on key transportation stages in real time.

After sales service

Our experienced engineering team brings together specialists from various fields and provides professional technical support for foundation construction, electrical line installation, production layout design, and other aspects. We provide comprehensive services, from equipment installation to commissioning.

Clients are provided with professional construction drawings (foundation, electrical diagrams, and other systems), making the installation and connection process simple and convenient.

The spare parts supply team ensures fast delivery of genuine components according to customer needs.

A world-class technical support service provides training in maintenance, troubleshooting and equipment repair.

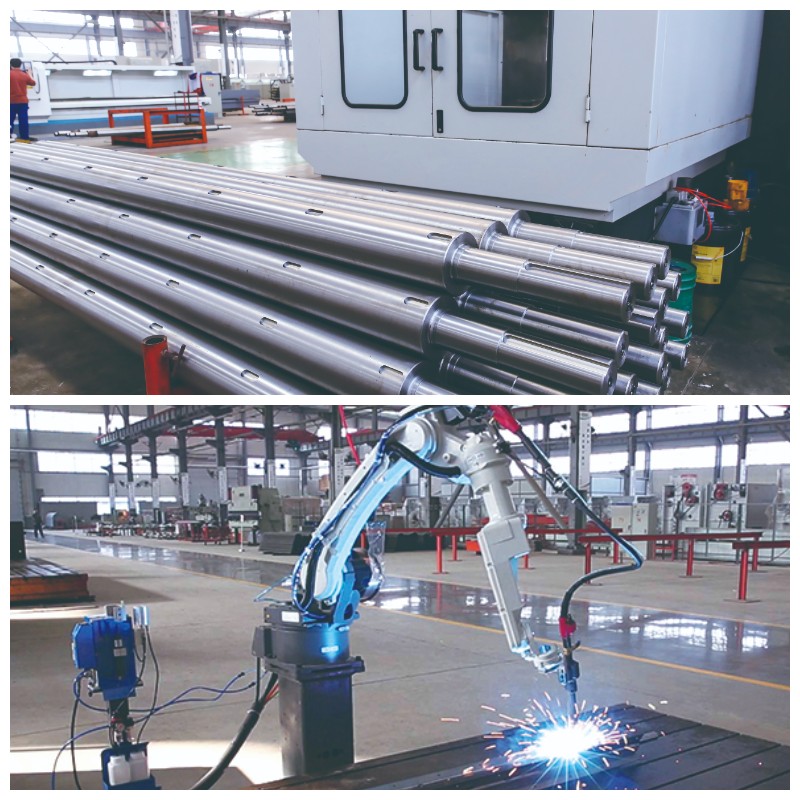

Product quality control

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. conducts strict comprehensive testing on every piece of equipment before shipment, including:

Visual inspection: Checking the product’s appearance – colour, shape, size, surface quality and compliance with technical requirements.

Functional testing: Verifying the correct operation of the machine through trial runs and performance testing using specialized equipment.

Checking markings and instructions: Checking the accuracy, legibility and completeness of markings and operating documentation in accordance with regulatory requirements.

Safety testing: Verification of compliance with electrical, mechanical and chemical safety standards.

Company information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a joint-stock enterprise belonging to the supply and marketing system of Shandong Province.

The company was founded in 1946 and combines research and development, high-precision manufacturing, marketing services and capital management in its activities.

The company specializes in mechanized, intelligent and digital cotton ginning systems, providing complete turnkey solutions.

The products are exported to more than 30 countries worldwide, and Shandong Swan has held a leading position in the domestic market for many years.

The sales and service network covers all major cotton producing regions.

Focusing on cotton ginning equipment, the company actively promotes the modernization and intellectualization of the cotton industry, develops the concept of "smart factories", strives to create the world's first brand in the field of cotton machinery, and expands its activities in the field of intelligent agricultural machinery and high-tech mechanical engineering.

The company has four technical centers and production bases: Jinan (Shandong Province), Wujiaqu (Xinjiang), Hailar (Inner Mongolia) and Montgomery (USA).

Its structure includes three national high-tech enterprises and six provincial innovation platforms.

For many years, Shandong Swan has been a leader in technological progress in the industry, recognized as a high-tech enterprise in Shandong Province, and is also an executor of national scientific and technological development programs (the 13th Five-Year Plan, etc.).