Equipment for primary processing of cotton

The new cotton feeding system ensures high impurity removal efficiency, uniform movement and dust-free operation.

Improved working chamber parameters ensure stable bale formation and free waste adjustment.

Intelligent control ensures safe operation with a reliability of ≥98%.

The mid-compartment seed discharge technology ensures high productivity, low energy consumption and adaptation to wet cotton.

Imported saws (USA) guarantee high productivity, durability and quality of ginning.

The scientific and rational design of the machine ensures stability, reliability and ease of maintenance.

The streamlined protective cover with visual control ensures safety and environmental friendliness.

Product Introduction

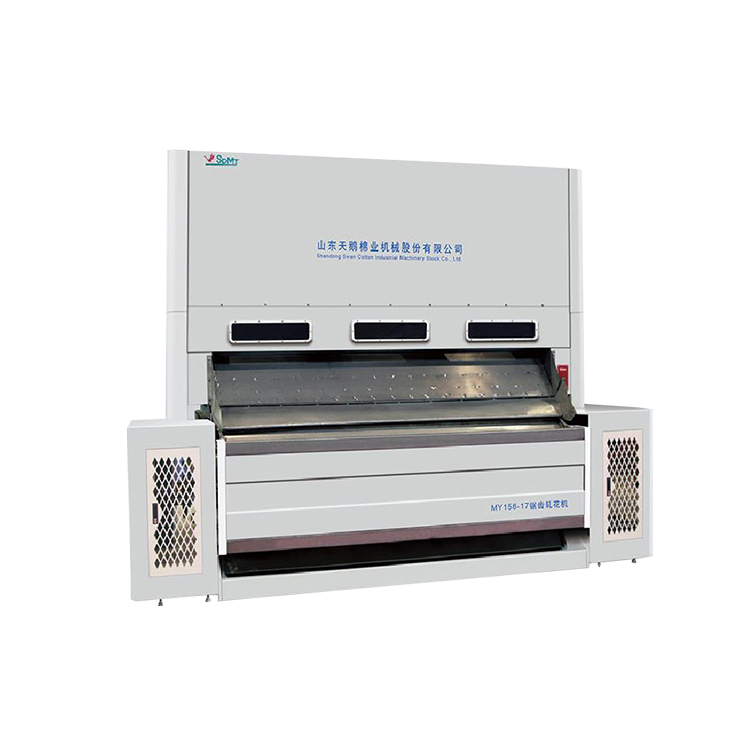

The MY158-17 cotton gin with saws is specifically designed for separating cotton fibers from cotton seeds and cleaning the seeds themselves. Equipped with high-quality imported components, the machine's design meets advanced international standards.

The processed fiber is characterized by high quality, low impurity content, excellent structure and high market competitiveness, which provides our customers with maximum economic benefit.

Specifications

Parameter

Meaning

Model |

MY158-17 |

Design capacity (kg/h) |

1100–1800 |

Installed capacity (kW) |

64.75 |

Gin quality |

Meets or exceeds national ginned cotton standards |

Noise level |

90 dB(A) |

Number of saws (pcs.) |

158 |

Saw diameter (mm) |

F406 |

Step between saws (mm) |

17 |

Brush cylinder diameter (mm) |

Φ380 |

Overall dimensions (W×D×H, mm) |

3138×4068×3508.5 |

Machine weight (kg) |

8100 |

Packaging and delivery

We provide customized packaging methods upon customer request.

Each vehicle is securely fastened and reinforced within the container to ensure safe delivery to the destination port.

The entire process of loading and sealing the container is recorded on photo or video—the entire process is transparent and controllable.

We partner with reliable shipping companies, and key transportation stages are updated in real time.

Product Quality Check

Visual inspection: The product's appearance is checked—color, shape, size, surface quality, etc. This is carried out visually or using measuring instruments.

Functional testing: The equipment's functionality is checked by test switching on and performance testing.

Safety tests: Compliance with electrical, mechanical and chemical safety requirements is checked.

Packaging inspection: We check the integrity of the packaging, the legibility of the labels, and the compliance of the packaging materials with standards. This ensures the safety of the equipment during transportation and storage.

Company information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a joint-stock company owned by the Shandong Provincial Supply and Marketing System. Founded in 1946, the company integrates research and development, precision manufacturing, marketing, and capital management, providing comprehensive solutions for the mechanization, intellectualization, and digitalization of cotton ginning operations.

Our products are exported to over 30 countries, and our domestic market share has held a leading position for many years. Our service network covers all major cotton-producing regions worldwide.

Based on the cotton gin business, the company actively promotes the modernization and intellectualization of the cotton industry, builds smart factories, strives to create the world's first brand in cotton machinery, and expands its activities in the fields of intelligent agricultural machinery and high-tech mechanical engineering.

The company has four technology centers and production bases - in the cities of Jinan (Shandong), Wujiaqu (Xinjiang), Hailar (Inner Mongolia) and Montgomery (USA), three national high-tech enterprises and six provincial innovation platforms.

For many years, the company has been a leader in technological progress in the industry, recognized as a high-tech enterprise of Shandong Province, is a technical support unit of national scientific and technological promotion programs, and is also a participant in the 13th Five-Year Plan project of the National R&D Program of China.

Questions and Answers (FAQ)

1. Question: Are you a factory or a trading company?

Answer: We are a factory. We have four production bases: our head office in Jinan, as well as branches in Xinjiang, Inner Mongolia, and Montgomery, USA.

2. Question: Where is your head office located? How can I visit you?

Answer: Our office is located in Jinan, Shandong Province, China. It's approximately a two-hour flight from Guangzhou or a 1.5-hour high-speed train ride from Beijing. We look forward to welcoming you!

3. Question: How do you control the quality of your products?

Answer: Swan was the first company in the industry to receive ISO9001 certification, as well as international quality system certificates from CNACR (China), RAB (USA), RVA (Netherlands), which are recognized in 20 countries around the world.

4. Question: What are your payment terms?

Answer: Terms are discussed individually. Advance payment (T/T) or irrevocable letter of credit (L/C) are acceptable.

5. Question: What is the production time?

Answer: Usually 20-50 days after receiving the advance payment or the original letter of credit.

If you have any other questions or requirements, please contact us and we will respond as soon as possible.