Grain dryer

Counter-current drying, holding and cooling provide the effect of natural grain drying.

Temperature control (high, medium, low) ensures drying quality and energy savings.

Uniform air distribution ensures equal heating and grain moisture.

Double shell with heat recovery reduces energy consumption and improves environmental friendliness.

Full mechanization of the process: online control, automatic regulation, video surveillance, alarm, one-click start.

Product presentation

The intelligent control system of the grain dryer is designed for the grain drying process. It uses advanced technologies and control systems that allow it to efficiently process large volumes of grain, ensuring its quality and safety during drying.

The intelligent control system of the grain dryer consists of the drying tower body, heating system, circulation fan, control system and other components. During the drying process, the grain is fed into a drying tower, where the air is heated by a heating system to create a hot stream. Hot air is evenly distributed throughout the grain mass using a circulation fan, due to which moisture from the surface and inside the grain is effectively evaporated.

At the same time, the control system monitors and regulates the temperature, humidity, air flow rate and other parameters inside the drying tower, ensuring the accuracy and stability of the entire drying process.

Specifications

Model |

Productivity (t/day) |

|||

Reducing humidity by 5% |

Reducing humidity by 10% |

Reducing humidity by 15% |

Reducing humidity by 20% |

|

SHSN-100 |

300 |

150 |

100 |

75 |

SHSN-150 |

450 |

225 |

150 |

112 |

SHSN-200 |

600 |

300 |

200 |

150 |

SHSN-300 |

900 |

450 |

300 |

225 |

SHSN-500 |

1500 |

750 |

500 |

375 |

SHSN-600 |

1800 |

900 |

600 |

450 |

Product Application

The intelligent grain dryer control system is widely used in the grain storage and processing industry. It is suitable for drying a variety of crops, including grains, legumes, oilseeds, and others.

By using intelligent grain drying towers, farmers and grain processing companies can more efficiently manage and protect grain resources, improve product quality, and reduce losses. This allows them to supply safer, higher-quality food products to the market.

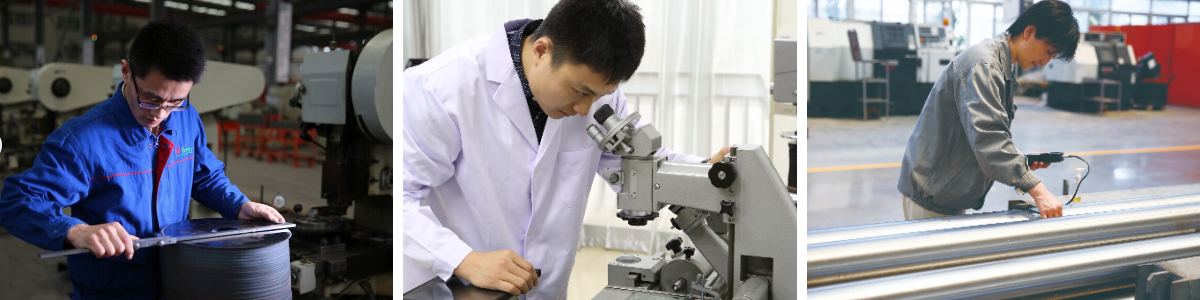

Product Inspection

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. Conducts strict comprehensive testing on each product before shipment, including the following steps:

(1). Appearance inspection: checking that the appearance of the product meets the requirements, including color, shape, size, surface quality, etc. Inspection is carried out visually or using auxiliary tools (for example, microscopes, measuring instruments).

(2) Functional testing: Verifying the correct operation of all product functions. Testing is performed by trial runs of the equipment, performing functional checks, or using specialized test equipment to confirm the product's characteristics and performance.

(3) Packaging inspection: checking the integrity of the packaging, the clarity of the markings, and the compliance of the packaging materials with established requirements. This ensures the safety of the product during transportation and storage, as well as its correct identification.

(4) Checking labels and instructions: checking the accuracy, clarity, completeness and compliance of labels and operating instructions with current regulations and standards.

Packaging and delivery

(1) Each vehicle is securely fastened and secured inside the container to ensure its safe delivery to the destination port.

(2) The entire process of loading products and sealing the container is recorded by photo or video, making the process completely transparent and controllable.

(3) Cooperation with reliable shipping companies ensures timely updates on key delivery stages in real time.

About Shandong Swan Cotton Industrial Machinery Stock Co., Ltd.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd.Swan is one of the leading manufacturers of cotton harvesting and ginning machines in China. The company was founded in 1946 and is a member of the Union of Supply and Marketing Cooperatives of Shandong Province. Combining research, design, production, and service, Swan provides comprehensive solutions for mechanized and intelligent cotton processing.

Swan products are exported to over 30 countries and firmly hold a leading position in the Chinese domestic market. Utilizing cutting-edge technologies, the company is actively implementing the concept of "smart manufacturing" and strives to become a global leader in cotton ginning equipment.

Today, Swan has four manufacturing and engineering centers—in Shandong Province, Xinjiang, Inner Mongolia, and the United States. The company is a high-tech enterprise, an official technical partner of China's national science and technology programs, and a recognized innovation leader in the industry.