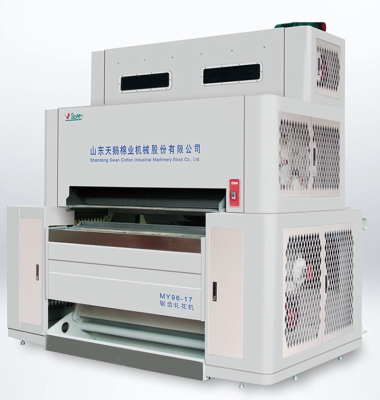

The MY109-19.2 raw cotton gin is designed primarily for separating fiber from seed and removing impurities from raw cotton. The machine features stable and high performance, meeting the processing needs of cotton producers worldwide.

Product Details

Product Introduction

Specifications

Parameter |

Meaning |

Productivity (kg/h) |

600–850 |

Power (kW) |

31.12 |

Quality of denim cotton |

Meets or exceeds the national standard for cotton of the same grade |

Noise level |

90 dB(A) |

Number of saws (pcs.) |

109 |

Saw diameter (mm) |

Φ320 |

Saw pitch (mm) |

19,4 |

Brush cylinder diameter (mm) |

Φ380 |

Dimensions (W×D×H) (mm) |

1708×3090×2284 |

Machine weight (kg) |

3000 |

Product Application

Client visit

About Shandong Swan Cotton Industrial Machinery Stock Co., Ltd.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a leading Chinese manufacturer of cotton harvesting and ginning equipment, founded in 1946 and part of the Union of Supply and Marketing Cooperatives of Shandong Province. The company integrates research and development, design, manufacturing, and service, offering comprehensive solutions for mechanized and intelligent cotton processing.

Swan products are exported to over 30 countries and enjoy a strong position in the Chinese domestic market. The company is actively implementing modern technologies and smart manufacturing concepts, striving to become a global leader in cotton ginning equipment.

Today, Swan operates four modern manufacturing and engineering centers in the provinces of Shandong, Xinjiang, Inner Mongolia, and the United States. The company is recognized as a high-tech enterprise, a partner in China's national science and technology programs, and is deservedly considered an innovation leader in the industry.

Leave your messages