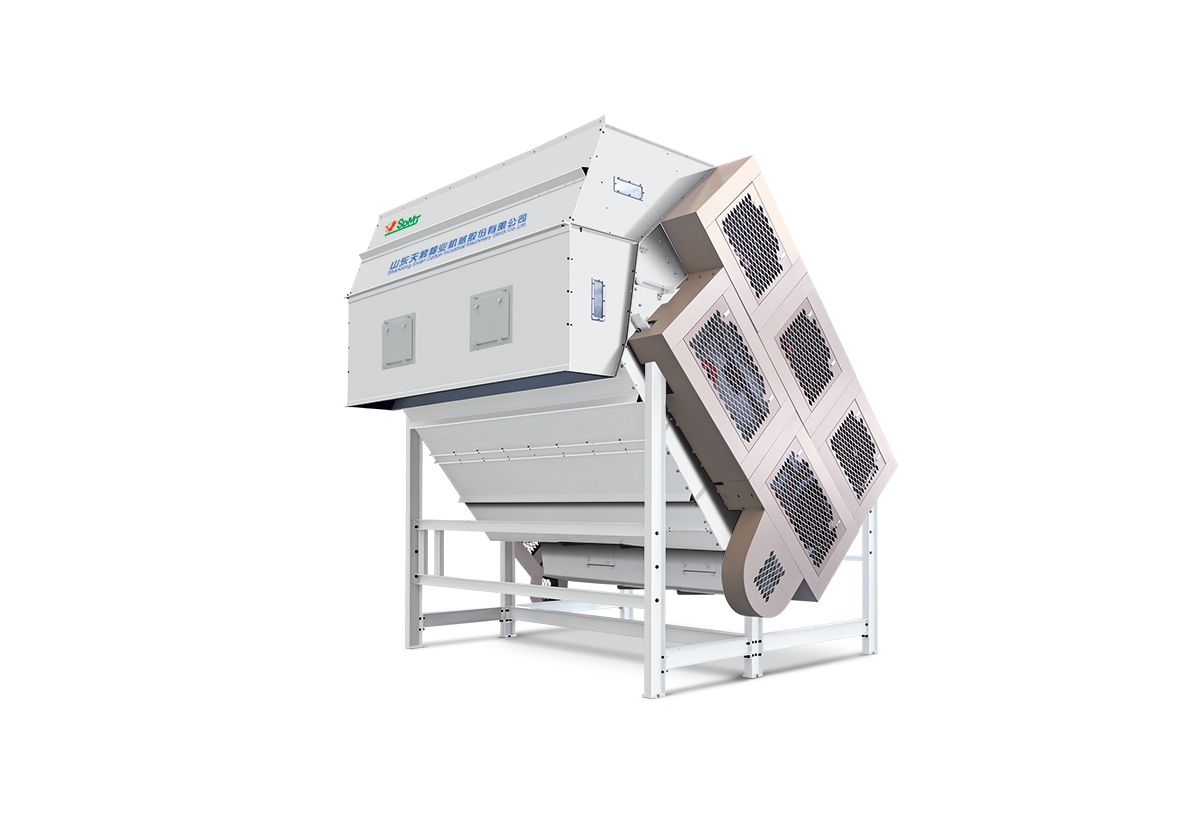

Two-stage raw cotton cleaning machine

The machine consists of an upper and lower part, which can work together or separately.

The multifunctional design reduces installation height, saving space and equipment costs.

Independent design of the upper and lower parts improves the efficiency of removing impurities and reduces cotton loss.

Cylinder with 14-sided serrated nails: high stability, low vibration, impurity removal rate ≥65%.

CNC machined serrated nails with a tapered ball head minimize fiber damage and snagging.

A protective casing with transparent elements, phosphating and powder coating provide corrosion resistance and an aesthetic appearance.

Product Introduction

Double-deck sorting machine for cleaning raw cottonA cotton gin is a piece of equipment used in cotton processing, primarily designed to remove impurities from cotton and raw cotton. The machine is highly efficient and easy to operate. It improves the quality and purity of cotton while reducing labor and the cost of manual ginning, thereby increasing productivity.

Scope of application

The main application is cleaning of machine-picked, quickly hand-picked and hand-picked cotton.

Specifications

Model

Productivity (kg/h)

Power (kW)

Overall dimensions (L×W×H) (mm)

Mass (kg)

MQZF-15 |

13,000–15,000 |

44 |

4310×4222×4247 |

13000 |

MQZF-12 |

10000–12000 |

37 |

3860×4222×4247 |

12000 |

MQZF-10 |

8000–10000 |

30 |

3100×4177×4247 |

11500 |

Note:

The indicated productivity corresponds to the processing of raw cotton of a standard grade with a moisture content of no more than 7%, while the quality of the produced fiber complies with the standard.

Packaging and delivery

Each vehicle is securely fastened and secured within the container to ensure safe delivery to the destination port.

The entire process of loading and sealing the container is recorded by photo or video, ensuring transparency and control of the entire process.

Delivery is carried out in cooperation with reliable shipping companies, with key stages of transportation updated in real time.

Product quality control

External inspection:The appearance is checked to ensure that it meets the requirements—color, shape, surface quality, etc. The inspection is carried out visually or using auxiliary instruments (e.g., microscopes, measuring instruments).

Functional tests:The correct operation of the product's functions is verified. This is performed by operating the equipment, performing functional tests, or using specialized test equipment to verify parameters and performance.

Safety tests:The products are checked for compliance with current safety standards and regulations (electrical, mechanical, chemical, etc.).

Packaging control:The integrity of the packaging, the clarity of the markings, and the compliance of the packaging materials with established requirements are checked. This ensures the safety of the product during transportation and storage, as well as its correct identification.

Company information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd.is a joint-stock company owned by the Xindong supply and marketing cooperative system. The company dates back to 1946. The company integrates R&D, precision manufacturing, marketing services and investment operations to provide comprehensive solutions and services for mechanized, intelligent and information-based cotton processing equipment.

The company's products are exported to more than30 countries, Adomestic market sharehas been a leader for many years. The sales and service network covers all major regions of the world's cotton production.

Based on productioncotton gin equipment, the company actively promotesmodernization and digitalization of the cotton industry, createsnew generation of “smart factories”, strives to becomeworld leader in cotton engineering, and also expands its activities in the fieldintelligent agricultural machineryAndhigh-tech mechanical engineering.

The company hasfour technical centers and production basesin citiesJinan (Shandong Province), Wujiaqu (Xinjiang), Hailar (Inner Mongolia)AndMontgomery (USA), hasthree national high-tech enterprisesAndsix provincial innovation platformsFor many years, Shandong Swan has beenleader in technical progress in the industryThe company is recognizedhigh-tech enterprise of Shandong Province, istechnical support for the State Program for the Promotion of Scientific and Technological AchievementsAndexecutor of the State R&D Program "13th Five-Year Plan".