Equipment for pre-cleaning of raw cotton

A patented product for high efficiency businesses, designed exclusively for machine cotton.

The feed and extraction system ensures efficient cleaning, uniform feed and no dust.

The improved working chamber ensures high productivity and processing quality.

Imported saws (USA) guarantee high yield, durability and excellent ginning quality.

The new adjustment system allows control of the fibre content of the cleaned seeds.

Intelligent control system ensures safe operation with reliability ≥98%.

The simple and rational design ensures stability, ease of maintenance and the use of modern technologies and materials.

Product Introduction

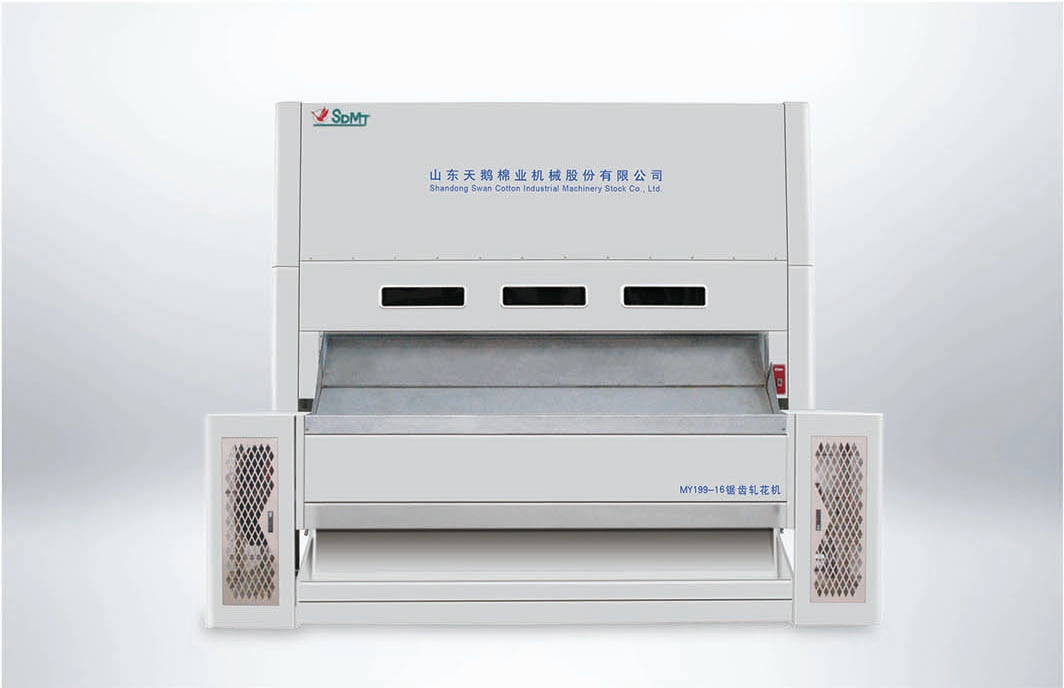

The MY199-16 cotton gin with saws is specially designed for separating fibers from cotton seeds and cleaning the seeds.

It is equipped with high-quality imported components, and its design meets international advanced standards.

The processed cotton fiber has high quality, low impurity content, excellent structure and high market competitiveness, creating higher economic value for customers.

Specifications

Parameter

Meaning

Model |

Mi199-16 |

Design capacity (kg/h) |

2000–3000 |

Installed capacity (kW) |

107.25 |

Ginning quality |

Meets or exceeds national ginned cotton standards |

Noise level |

90 dB(A) |

Number of saws (pcs.) |

199 |

Saw diameter (mm) |

F406 |

Distance between saws (mm) |

16 |

Brush cylinder diameter (mm) |

Φ450 |

Overall dimensions (W×D×H, mm) |

3676×4560×3558.5 |

Machine weight (kg) |

11000 |

Packaging and delivery

We provide customized packaging options according to customer requirements.

Each vehicle is securely fastened and reinforced inside the container to ensure safe delivery to the destination port.

The entire process of loading and sealing the container is documented by photo or video recording, making the process transparent and fully controllable.

We partner with reliable transport and shipping companies, ensuring prompt updates on key stages of transportation.

Product Quality Check

Visual inspection: The product's appearance—color, shape, dimensions, surface quality, and other parameters—is checked. The inspection is performed visually or using measuring instruments (e.g., microscopes or measuring devices).

Functional testing: Verifies the correct operation of the equipment. Operational tests, functional testing, and performance verification are performed using specialized equipment.

Safety Testing: Ensures product compliance with electrical, mechanical and chemical safety standards and regulatory requirements.

Packaging inspection: We check the integrity of the packaging, the legibility of the markings, and the compliance of the packaging materials with standards. This ensures the safety of the equipment during transportation and storage, as well as the ability to accurately identify the product.