Functional testing: assessing the correct operation of all product functions. Conducted through operational testing or using specialized equipment to check performance and functionality.

Checking labelling and operating instructions: checking the accuracy, completeness and legibility of labels and instructions, as well as their compliance with current regulations and standards.

Safety testing: checking the compliance of products with safety standards and regulations, including electrical, mechanical, chemical and other types of safety.

Testing of materials and components: assessment of the conformity of the materials and components used with the established requirements using methods of chemical and spectral analysis, tensile testing and other verification procedures.

Saw fiber cleaner

The equipment is made from special materials, has a rational design and reliable operation.

The shell (gear) is made of a unique material with a specially shaped tooth - durable, cleans effectively, and causes minimal damage to the fiber.

A special knife for removing foreign matter ensures maximum removal of impurities with minimal fiber loss.

State-of-the-art pressing, separation and feeding design reduces fiber damage and equipment failure.

The new roller and fixed feed point design ensures stable carding and eliminates the emission of “white cotton”.

Rational distribution of the discharge knife zones improves cleaning and lint quality.

1. Product description

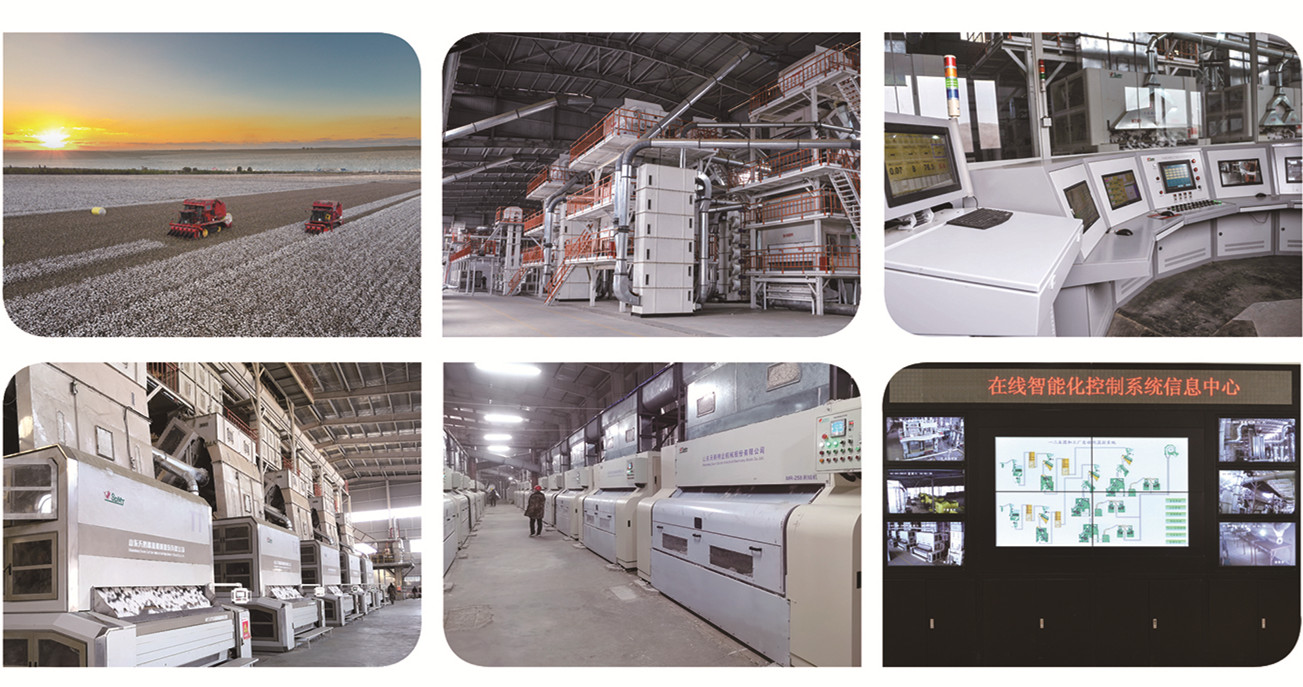

Saw-type lint cleaners are widely used to improve the overall quality of cleaned cotton. They remove foreign objects and unwanted short fibers after ginning. The Swan lint cleaner is characterized by stable operation, high product quality, and significant improvement in lint properties.

2. Main technical parameters

| Model | Slide roller diameter (mm) | Estimated productivity (kg/h) | Installed capacity (kW) | Overall dimensions (mm) | Mass (kg) |

|---|---|---|---|---|---|

| MQP-400x2000H | Φ400 | 1000~1800 | 19 | 2800x1325x2285 | 3400 |

| MQP-400x2500H | Φ400 | 1300~2100 | 22.5 | 3300ks1325ksskh | 4500 |

| MQP-400x3400H | Φ400 | 2400~3600 | 37.5 | 4300x1510x2295 | 7000 |

| MQP-600x2000H | Φ600 | 1200~2000 | 22.5 | 2800x1600x2615 | 4100 |

| MQP-600x3000H | Φ600 | 2400~3600 | 27.5 | 3750x1660x2615 | 6600 |

3. Packaging and delivery

Our qualified packing and loading team ensures the safety and integrity of goods at every stage of preparation for transportation.

Each piece of equipment is carefully secured and secured within the container for safe delivery to the destination port.

The entire process of loading and sealing the container is documented using photographs and videos, making the procedure completely transparent and controllable.

We partner with trusted shipping companies, and key delivery stages are tracked and updated in real time.