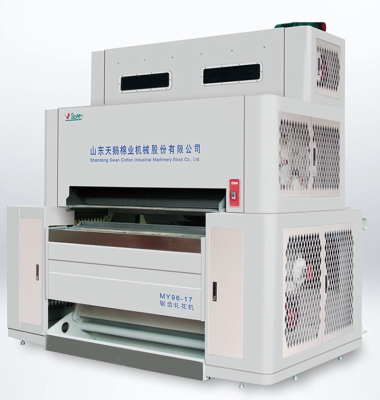

fiber press

The modular design with pin connection ensures high rigidity, convenient installation and reliable, stable operation.

The high-performance, one-piece cotton chamber prevents expansion during pressing, while the suction casing prevents fibre scattering.

The patented heavy-duty hook system offers low failure rates and durability.

Hydraulic step-by-step camera lift control with automatic locking reduces shock and improves safety.

The hydraulic system with recirculation cooling and Parker (USA) components operates reliably; the PLC system ensures precise control, automatic diagnostics, and uniform bale weight.

Product presentation

A cotton press is a device designed for pressing and packaging cotton fiber. Its primary function is to compress the loose fiber into compact bales for easy storage and transportation. Pressing significantly reduces the fiber volume, saving warehouse space and simplifying loading and transportation.

The fiber press designed and manufactured by our company fully meets the production requirements of cotton gins both in China and abroad. The equipment is characterized by stable and efficient operation and is widely used in the world's major cotton-producing regions—Xinjiang in China, Brazil, Central Asian countries, and elsewhere.

Specifications

Basic parameters |

Productivity (bales/h) |

|||

20 bales / 4540 kg |

25 bales / 5675 kg |

30 bales / 6810 kg |

40 bales / 9080 kg |

|

Nominal working pressure (kN) |

4000 |

|||

Bale size (mm) |

1400 × 530 × 700 |

|||

Bale mass (kg) |

227 ± 10 |

|||

Pressing height (mm) |

485–508 |

|||

Power (kW) |

85 |

115 |

123 |

153 |

Machine weight (kg) |

45000 |

|||

Product Application

Product Inspection

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. conducts rigorous testing on every product before it leaves the factory. Key inspection steps include:

(1). Appearance inspection: checking the conformity of the product’s appearance with the requirements – color, shape, dimensions, surface quality, etc. The inspection is carried out visually or using auxiliary instruments (e.g. microscopes, measuring instruments).

(2) Functional testing: checking the correct operation of all equipment functions. This is carried out through a trial run or using specialized test equipment to confirm the characteristics and reliability of operation.

(3). Checking Labels and Instructions: Verifies that labels and operating instructions are accurate, legible, complete, and consistent with applicable standards and regulations.

(4) Safety testing: assessing the product's compliance with safety requirements and applicable standards. Includes electrical, mechanical, and chemical safety testing.

Packaging and delivery

(1) Each machine is securely fastened and reinforced inside the container, ensuring safe delivery to the destination port.

(2) The entire process of loading equipment and sealing the container is recorded by photo or video—the entire process is transparent and controllable.

(3) The company cooperates with reliable shipping lines; information on key stages of transportation is updated in real time.

Client visit

About Shandong Swan Cotton Industrial Machinery Stock Co., Ltd.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a leading manufacturer of cotton harvesting and ginning equipment in China. Founded in 1946, the company is a member of the Union of Supply and Marketing Cooperatives of Shandong Province. Combining research, design, production, and service, Swan offers comprehensive solutions for mechanized and intelligent cotton processing.

Swan products are exported to over 30 countries and hold a strong position in the Chinese domestic market. Utilizing cutting-edge technologies, the company is actively implementing the concept of "smart factories" and strives to become a global leader in cotton ginning equipment.

Swan currently operates four modern manufacturing and engineering centers—in Shandong Province, Xinjiang, Inner Mongolia, and the United States. The company is a high-tech enterprise, a partner of China's national science and technology programs, and a recognized innovation leader in its industry.