Self-propelled (or mounted) round baler

High performance: Dual positive feed pressure roller increases pick-up capacity and efficiency.

Anti-clogging system: the operator can quickly clear a blockage via the terminal by opening the lower bin.

Double binding system: twine and net support; bale density is controlled via terminal.

Good adaptability: the improved gauge wheel ensures operation on uneven and different types of terrain.

Minimal maintenance: Conveyor assembly and strict control reduce the need for maintenance.

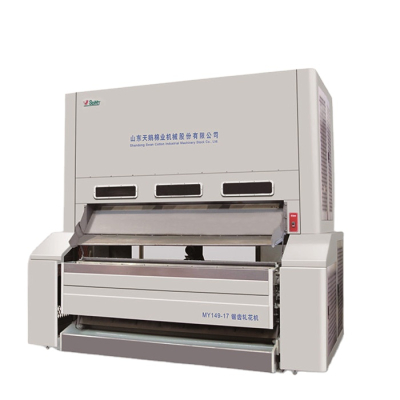

1. Product Introduction

A round baler is a modern agricultural machinery designed for collecting, pressing and packaging various crop residues (grass, hay, straw, etc.) into dense roll bales. The design uses a rotating pressing mechanism and a feeding system to ensure uniform compaction of the material. Finished rolls are distinguished by high density, durable external and softer internal structure, which provides excellent ventilation, protection from moisture and ease of storage.

Modern roll balers are widely used in farming and agro-industrial enterprises due to their productivity, reliability and ease of maintenance. If you are looking to buy a round baler, the model from Shandong Swan is an excellent choice - it combines high efficiency, economical energy consumption and durable design, ensuring stable operation even in the most difficult field conditions.

2. Technical specifications

Indicator

A unit of measurement

Meaning

Required tractor power |

kW |

≥80 |

Construction |

/ |

Spring tooth |

Dimensions |

mm |

4200×2960×2400 |

Weight |

kg |

4200 |

PTO speed |

rpm |

540–1000 |

Pick chamber width |

mm |

2200 |

Press chamber diameter |

mm |

1200 |

Baling chamber length |

mm |

1400 |

Number of rows of spring teeth |

/ |

5 |

Distance between teeth |

mm |

70 |

Number of knives |

pcs |

12 |

Theoretical cutting length |

mm |

65 |

Working speed |

km/h |

2–6 |

Roll weight |

kg |

Straw ≥350 / Forage grass ≥500 |

3. Product quality control

Shandong Swan Cotton Industrial Machinery Co., Ltd. conducts strict comprehensive testing on every unit of equipment before shipment, including:

External inspection – checking the color, shape, size and condition of the surface visually or using measuring instruments.

Functional testing – testing the machine’s performance characteristics in various modes.

Packaging control - checking the integrity of the packaging, legibility of labeling and compliance with transportation requirements.

Checking labeling and instructions ensures accuracy, completeness, and compliance with regulatory standards.

4. Packaging and delivery

Each vehicle is securely secured in a container for safe transportation to the destination port.

The entire container loading and sealing process is captured on photo or video, making the delivery transparent and controllable.

The company partners with trusted shipping lines, and information about key delivery stages is updated in real time.