Gin machine

Designed for processing raw cotton, suitable for manual and machine collection.

Special pre-cleaning structure for natural classification and sifting.

Minimal mechanical damage to cotton, preservation of fiber and seeds after cleaning.

The large working box and increased distance between the saws ensure the correct roller density, preservation of fiber length and seed integrity.

Special structure of the working box with flexible opening/closing and free adjustment of debris removal.

The application of hydrodynamic principles improves cleaning efficiency and fiber quality.

The equipment adapts to the condition of the cotton for easy adjustment.

? 1. Introduction to the Product

Cotton gin machine model MY126-19.5

The MY126-19.5 cotton gin machine is specially designed for separating fiber from cotton seeds and cleaning cotton seeds. It is equipped with high-quality imported components, and its design concept meets international leading standards. The cotton fiber (lint) obtained after processing is characterized by a high level of quality, minimal content of foreign impurities and correct structure, which provides it with a strong competitive position in the market and allows our customers to receive higher economic returns.

⚙️ 2. Technical Specifications

Parameter |

Model |

Model |

MY126-19.5 |

Designed output |

800-1300 |

Equipped power |

51.62 kW |

Lint ginning quality |

Meets or exceeds the national standard for ginned cotton |

Noise level |

90 dB |

Number of saw blades (Pieces of saws) |

126 pcs. |

Diameter of saw blades |

320 mm |

Saw spacing |

19.4 |

Diameter of brush cylinder |

380 |

Overall dimensions (W*D*H) |

3232*3670*3654 |

Machine weight |

5200 |

? 3. Packaging and Delivery

Providedindividual(customized) packaging for customers.

(1) Each piece of equipment is carefully secured and further reinforced inside the container, ensuring its safety and security during transportation to the destination port.

(2) All stages of loading and container sealing are documented using photography and video, ensuring complete transparency and traceability of the entire process.

(3) We work with trusted shipping partners, with key transportation stages and time points tracked and updated in real time.

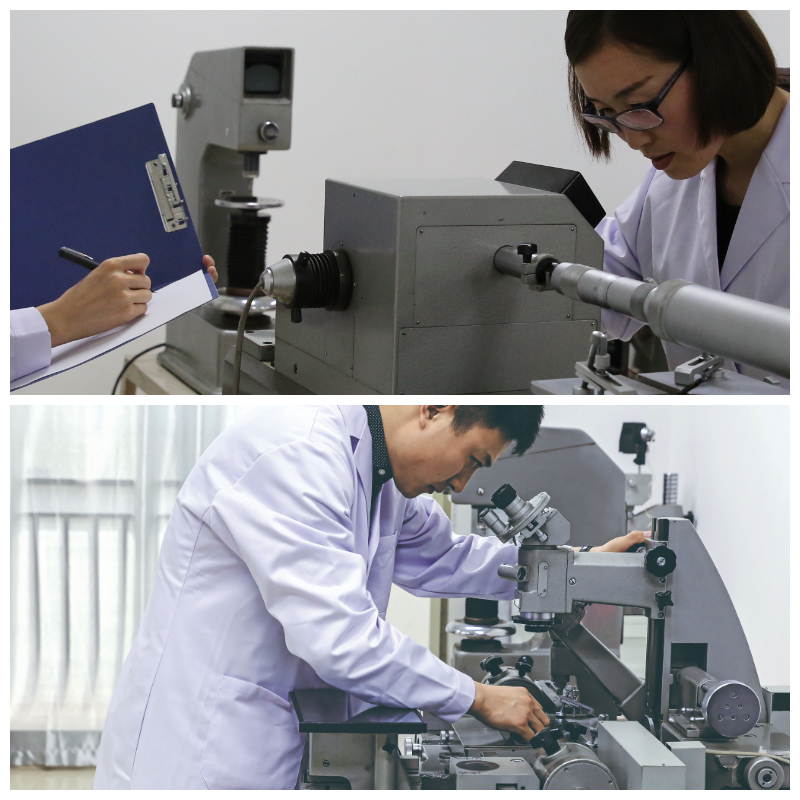

? 4. Product Inspection

We have implemented a strict comprehensive quality control system, under which every product manufactured by the company undergoes comprehensive testing. Key procedures include the following steps:

(1). Visual appearance check:

Evaluation of product conformity with established requirements for appearance, including color, geometric shape, dimensions, and surface condition. Inspection is performed visually or using auxiliary means, such as measuring instruments and optical equipment.

(2). Functional performance testing:

Confirmation of the correct operation of a product through its practical use, conducting targeted functional tests, or using specialized test setups to evaluate operating parameters and performance properties.

(3). Safety compliance testing:

Testing products for compliance with current safety standards and regulations, including electrical, mechanical and chemical protection testing.

(4). Packaging and labeling inspection:

Assessing the strength and integrity of the packaging, the clarity and accuracy of the markings, and the compliance of the packaging materials with established requirements. This stage ensures the safety of the product during storage and transportation, as well as its correct identification.