Self-propelled cotton harvester with bale press

High collection speed, minimal fiber damage, low impurity levels and preservation of the natural shape of the cotton.

A 777-hp Cummins engine, all-wheel drive, and high performance. The high-speed PRO16 harvesting head achieves a maximum harvesting speed of 7.1 km/h—30% faster than a standard 6-row box harvester.

Packaging system: controlled, continuous, uniform ejection + forced feed – reliable protection against blockages; module diameter and bale weight (700–2200 kg) are adjustable to field conditions.

A highly efficient, powerful fan creates a strong air flow, effectively preventing blockages and providing excellent extraction.

Premium cabin of our own design: electric gearbox, hydraulic clutch, ergonomic HMI interface – maximum operator comfort.

CAN bus-based intelligent control system: automatic monitoring, emergency alarm, humidity control, automatic leveling, autonomous driving functions and other advanced features.

Product Introduction

The 4MZD-6 six-row self-propelled baling cotton harvester is a new generation of products independently developed by our company according to market demand. It is capable of efficiently harvesting and pressing cotton, provides convenient transportation and can significantly reduce cotton losses during transportation. Currently, this model is widely used in cotton harvesting in Xinjiang, China's main cotton producing region. Due to the high purity of collection, low failure rate and stable operation, the equipment has received unanimous positive feedback from users.

Product characteristics

(1) The cabin is made in the style of a passenger car: luxurious and comfortable; The seats and controls can be adjusted to suit the operator's needs. Equipped with air conditioning, USB port and 12V power supply, which provides the user with more comfortable working conditions.

(2) Improved service: Each cotton harvester is assigned 2-3 maintenance and repair technicians to ensure smooth operation and prompt troubleshooting. There are spare parts warehouses in the equipment operating areas, ensuring a 24-hour supply of components, so customers can enjoy the reliability and high quality of original spare parts.

(3) Enhanced Performance: Equipped with a powerful 770 HP Cummins engine. and the latest design of the harvesting head; The maximum cleaning speed reaches 7.1 km/h, and overall productivity increases by more than 30%.

(4) Intelligent control: The status and operating parameters of the combine harvester are displayed in real time on the human-machine interface, allowing users to quickly and timely make relevant decisions and plan work.

Specifications

| Parameter | A unit of measurement | Meaning |

Machine parameters |

||

Own weight |

T |

30 |

Travel speed |

Cotton field, 1st gear |

km/h |

Cotton field, 2nd gear |

||

Highway, 1st gear |

||

Highway, 2nd gear |

||

Engine power |

kW |

570 |

Minimum turning radius |

m |

6,7 |

Dimensions (in transport position) L×W×H |

mm |

11940×3200×4360 |

Dimensions (in working position) L×W×H |

mm |

10135×5945×5245 |

Wheelbase |

mm |

4318 |

Drive type |

— |

Full (4WD) |

Cleaning head parameters |

||

Number of harvesting heads |

pcs. |

6 |

Number of seats (tubes) |

pcs. |

Front - 16, rear - 12 |

Number of spindles per seat |

pcs. |

20 |

Total number of spindles |

pcs. |

3360 |

Operating parameters |

||

Cotton module weight |

kg |

700–2200 |

Fuel tank capacity (diesel) |

l |

1400 |

Volume of the washing liquid tank |

l |

1363 |

Oil tank capacity (lubricant) |

l |

257 |

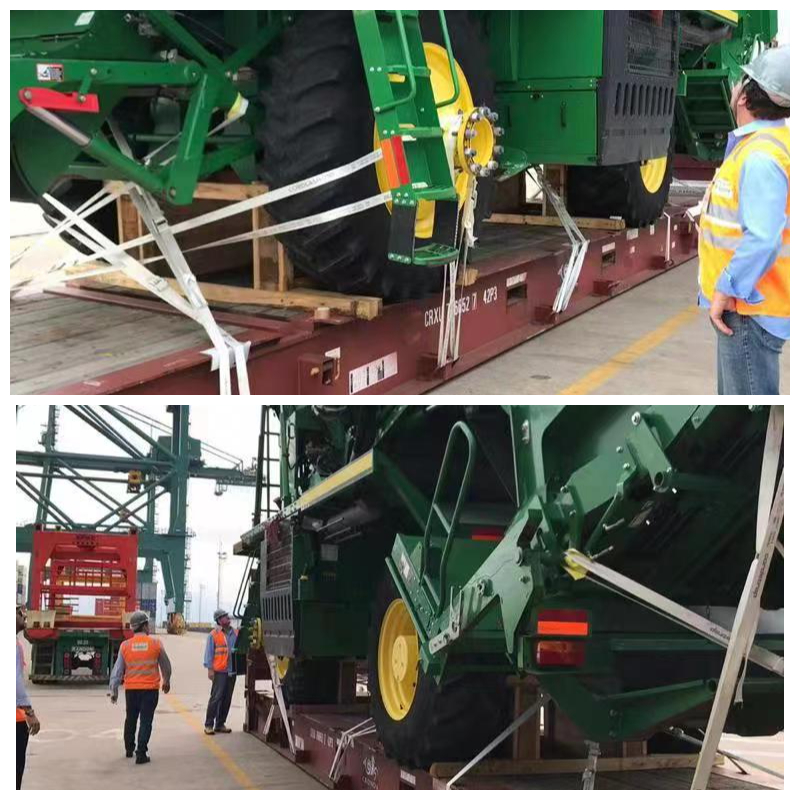

Special transportation solution

Based on previous delivery experience, the design and dimensions of the cotton harvester differ from standard equipment. Therefore, during international shipments, we use special packaging and securing systems to ensure the integrity and safety of the product.

Product quality control

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. conducts strict due diligence checks on every product leaving the factory. The main stages of control include:

(1) External inspection: checking whether the product's appearance meets the requirements, including color, shape, size, surface quality, etc. Inspection can be carried out visually or using auxiliary instruments (e.g. microscopes, measuring instruments).

(2) Functional testing: checking the correct operation of all functions of the product by operating it in test mode or using specialized equipment to confirm performance and operability.

(3) Checking the labeling and operating instructions: the labels and user manual comply with the requirements for accuracy, clarity, completeness and regulatory standards.

(4) Safety testing: checking the product's compliance with applicable safety standards and regulations, including electrical safety, mechanical safety, chemical safety, etc.

Company information

"Shandong Swan Cotton Industrial Machinery Stock Co., Ltd." is a public company owned by the Shandong Provincial Supply and Marketing Cooperative. Its predecessor was founded in 1946. The company integrates research and development, precision manufacturing, marketing services and capital operations into a single complex and specializes in providing comprehensive solutions and services for the supply of mechanized, intelligent and information-enabled cotton processing equipment. Products are exported to more than 30 countries. For several years, the company has occupied a leading position in the Chinese domestic market. Its service and distribution network covers all major cotton regions of the world.

Based on the production of cotton harvesting equipment as its core business, the company actively promotes the modernization and transformation of the cotton industry, creates a new era of smart factories, strives to become the world leader in the field of cotton harvesting equipment, expands its presence in the intelligent agricultural machinery segment, and confidently ranks among the world-class high-tech equipment manufacturers.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. has four technical centers and production sites in Jinan (Shandong Province), Wujiaqu (Xinjiang), Hailar (Inner Mongolia) and Montgomery (USA), owns three national high-tech enterprises and six provincial innovation platforms, leading the technological development of the industry for many years. The company is a high-tech enterprise in Shandong Province, a technical executor of the National Program for the Priority Introduction of Scientific and Technological Achievements, as well as a executor of key projects of the National Research and Development Program within the framework of the 13th Five-Year Plan.

For more video information, please visit our YouTube channel:

https://www.youtube.com/@SwancottonMachinery