Online cotton processing control system

Automatic cotton feeding system + overflow system: ensures a stable, continuous supply of raw cotton; excess is sent to a reserve. Guarantees full capacity, reduces manual labor, and reduces downtime due to raw cotton shortages.

Automatic bag loading: minimizes forklift use, saves fuel, reduces labor costs and improves safety.

Video surveillance system: HD cameras are installed in key areas (reception, transport, pressing, baling, unloading, and seed cleaning); a 55-inch screen is located between machines for easy monitoring of production.

High automation: the entire line is serviced by just 9 operators, distributed across key areas.

Turnkey modular delivery: equipment is delivered factory-ready, significantly reducing installation time and costs.

Product Introduction

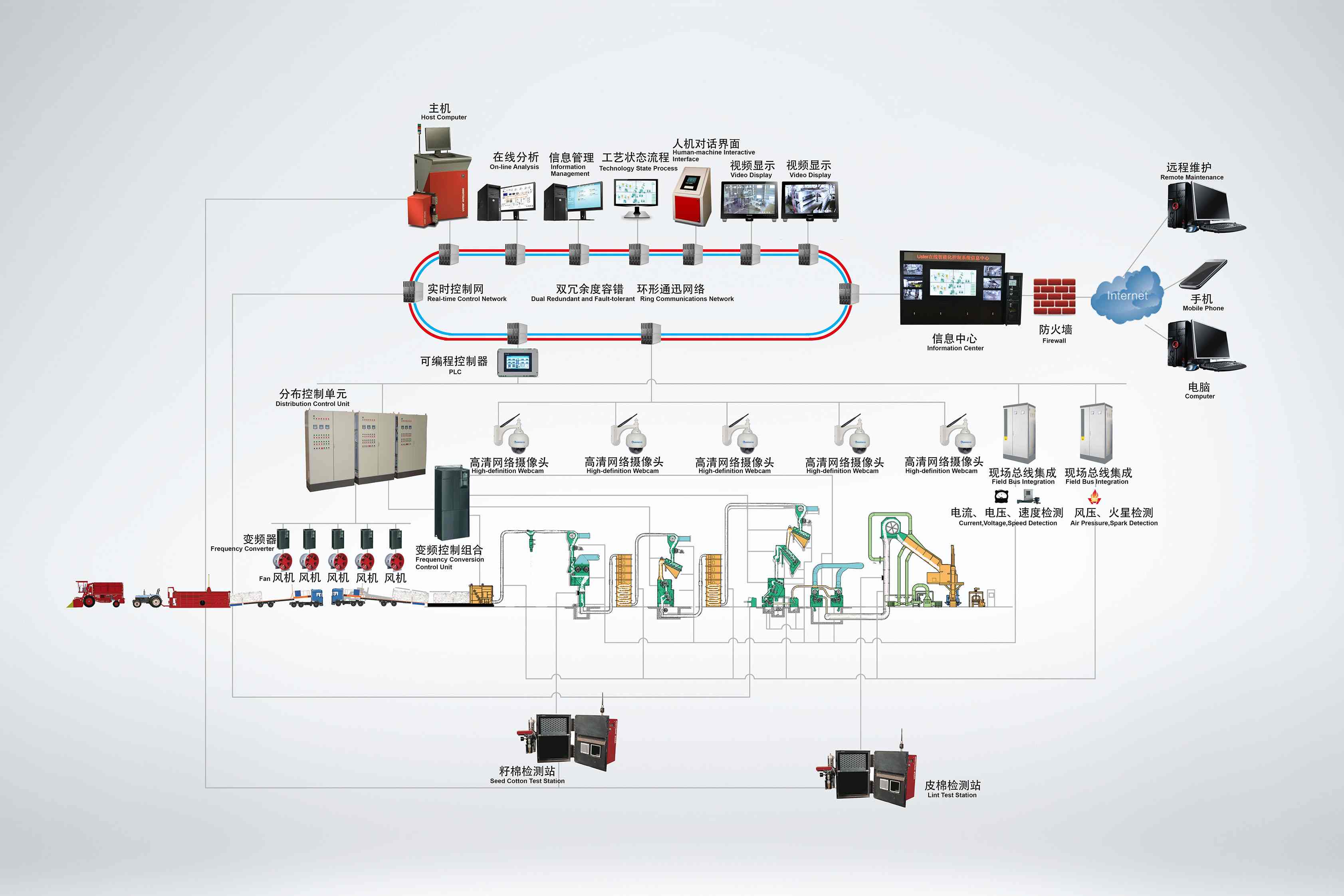

System for online monitoring of cotton processing quality and intelligent control

Integrating the world's advanced technologies, the system provides real-time online monitoring of key quality indicators of cotton processing, automatic optimization and adjustment of technological parameters, fully implementing the long-standing industry concept of “selection of equipment depending on the properties of cotton.” Quality parameters such as impurity content, moisture content and color grade of both raw (raw cotton) and purified fiber are tested online. Based on the data obtained, the optimal technological mode is promptly adjusted, and appropriate processing processes and equipment settings are selected to improve the quality of the finished cotton fiber.

System composition

Online monitoring system

The key quality parameters of raw cotton and purified fiber are monitored online using the same technology and monitoring standards as HVI equipment. During production, digital and video signals are collected in real time, analyzed, and processed to control equipment operation and promptly adjust parameters.

Executive regulatory system

Automatically adjusts equipment parameters and process modes in accordance with an optimized processing plan provided by an intelligent analytical system.

Management Information System

Enables the collection, analysis, and processing of all types of production data, creating the conditions for accurate calculation of the cotton gin's economic indicators. It enables the rapid collection of information from multiple production lines, facilitating resource sharing and streamlining management.

Remote technical support system

Provides remote technical support and service through secure and reliable communication channels.

Intelligent analytical system

Automatically compares online cotton quality data with preset target values and generates an optimized processing plan at any time.

Security system

A comprehensive suite of intelligent safety devices ensures the safety of personnel and equipment, eliminating the risk of fire, injury, and other safety hazards.

Energy saving system

Provides online automatic regulation of the entire power system, achieving high efficiency and energy savings.