Three-row self-propelled cotton harvester with crop pressing function

1. Cummins engine, 325 hp, electronically controlled hydraulic transmission, optional all-wheel drive, max. harvesting speed - 7.1 km/h.

2.PR016 assembly head - optimized spindle path and drum speed; Collection efficiency up to 93%, minimal fiber damage and low impurity content.

3. Controlled uniform feed + forced loading - reduces clogging; module diameter is adjustable to field conditions.

4. Premium cabin of our own design: gearbox with electro-hydraulic shifting, fluid coupling, ergonomic HMI interface – maximum operator comfort.

5. Intelligent control via CAN bus: auto-monitoring, emergency alarm, humidity measurement, etc.

6. Imported electronics – reliability and stability; key components – in-house development – low operating costs.

7. Own management software – flexible updating to meet product development needs.

8. Proven 6-row design with automatic dimension adjustment – convenient for transportation, road use and maintenance.

9. Service and sales network - in all cotton regions of Xinjiang: operator training, maintenance, guarantee of trouble-free operation.

Product presentation

The 4MZD-3 cotton harvester with a three-row harvesting system is our company's latest development, created in response to market demand. This model is already being successfully used in cotton harvesting in Xinjiang, China's main cotton-growing region. Thanks to its excellent maneuverability, high reliability, low breakdown rate, and stable performance, the harvester has received unconditional recognition from farmers.

Key Benefits

Luxury cabin in automotive style

An ergonomic workstation with an adjustable seat and controls to suit any operator preference. Standard equipment includes air conditioning, a USB port, and a 12V power outlet—all for maximum comfort while working.Full turnkey service support

Each combine is assigned a team of 2-3 certified maintenance engineers, ensuring smooth operation and prompt troubleshooting directly in the field. Warehouses with genuine spare parts are located in the operating areas, guaranteeing 24/7 supply and maintaining high-quality repairs.High performance

Equipped with a powerful Cummins diesel engine (325 hp, 424 kW) and a modern three-row cleaning head, the machine has a maximum working speed of 7.1 km/h, ensuring efficient cleaning even in tight deadlines.Intelligent control system

All key machine operating parameters are monitored in real time. Based on the collected data, the process can be adjusted immediately and the cleaning plan optimized.

Specifications

| Parameter | Unit of measure | Meaning |

General Settings |

||

Curb weight |

T |

24 |

Movement speed (field): |

km/h |

0–7,1 |

Travel speed (road): |

km/h |

0–15 |

Engine power |

kW (hp) |

424 (325) |

Min. turning radius |

m |

6 |

Dimensions (transport position, L×W×H) |

mm |

11,010 × 3,300 × 3,900 |

Dimensions (working position, L×W×H) |

mm |

9680 × 4200 × 4600 |

Wheelbase |

mm |

4095 |

Drive |

— |

Full (4WD) |

Cotton picking head |

||

Number of heads |

pcs. |

3 |

Number of spindle slots: front / rear |

pcs. |

16 / 12 |

Spindles per socket |

pcs. |

20 |

Total number of spindles |

pcs. |

1 680 |

Operational volumes |

||

Cotton module weight |

kg |

1400 |

Fuel tank (diesel) |

l |

600 |

Washing liquid tank |

l |

700 |

Lubricant reservoir |

l |

140 |

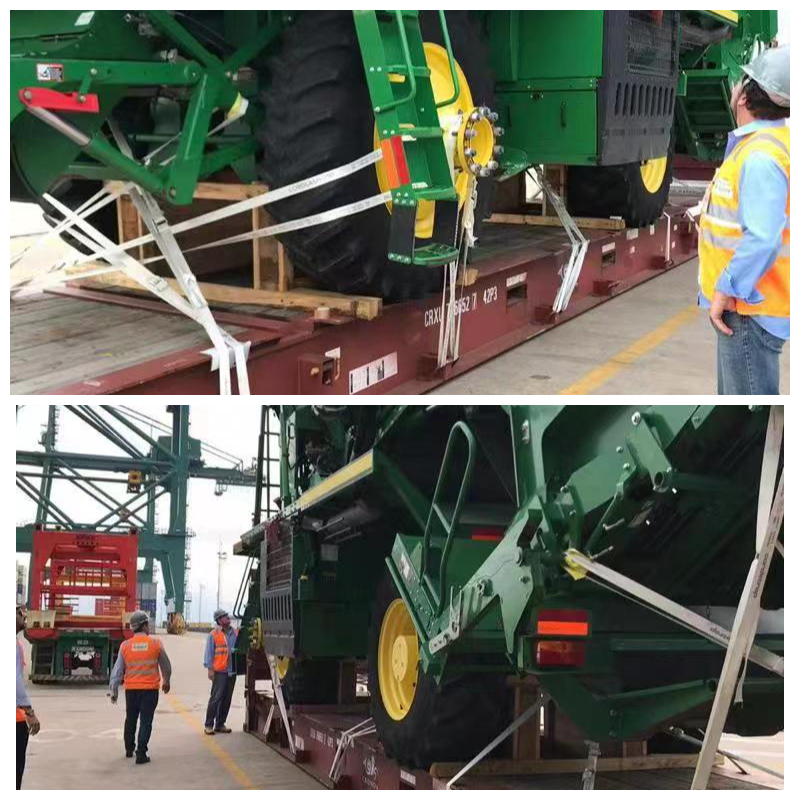

Transportation Features

Given the unique dimensions and design features of the cotton harvester, which distinguish it from standard agricultural machinery, we use specialized packaging and securing solutions for international shipments. This ensures the integrity of the equipment during delivery anywhere in the world.

Quality control

Each unit of equipment undergoes strict multi-stage control at the Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. plant:

External inspection – checking the color, shape, size and quality of surfaces (visually or using measuring instruments).

Functional testing is testing of all systems in operating mode using specialized equipment.

Checking labelling and documentation – ensuring that labels and manuals comply with legal requirements and international standards.

Safety - assessment of compliance with electrical, mechanical and chemical safety standards.

About the company

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a publicly traded company within the Shandong Provincial Supply and Marketing Cooperative. The company's history dates back to 1946. Today, the company integrates R&D, precision manufacturing, global marketing, and financial management, offering customers comprehensive turnkey solutions for mechanized, digital, and intelligent cotton processing.

Products are exported to over 30 countries, and in China, the Shandong Swan brand has been the sales leader for many years. The service network covers all key cotton-growing regions of the world.

With cotton harvesting equipment as its core business, the company is actively promoting the digital transformation of the cotton industry, creating "next-generation smart factories," and striving to become the world's number one cotton machinery manufacturer. At the same time, Shandong Swan is confidently developing its intelligent agricultural machinery business and entering the high-tech industrial equipment market.

The company has four research and development centers in Jinan (Shandong), Wujiaqu (Xinjiang), Hailar (Inner Mongolia) and Montgomery (USA), and owns three national high-tech enterprises and six provincial innovation platforms.

Shandong Swan is a recognized leader in technological progress in the industry, an official executor of the National Program for Priority Implementation of Scientific and Technological Achievements, and a leading participant in key projects within the framework of the national research and development program "13th Five-Year Plan".