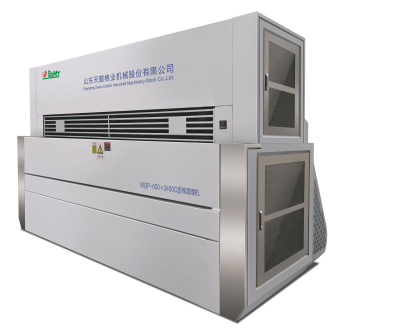

Cottonseed sawing debinding machine

The new working chamber design ensures smooth operation, high short fiber yield and minimal seed damage.

Trapezoidal stiffeners and galvanic coating increase strength and prevent fiber snagging.

Hydraulic opening/closing of the chamber ensures stable movement without impact.

Automatic installation and removal of the saw cylinder reduces labor costs.

Cylinder life cycle management system with replacement reminder.

The double pressure plate bearing assembly facilitates cylinder removal.

The dual fluff extraction system effectively removes short fibres.

Automatic seed feed adjustment ensures optimal operation and energy savings.

Product Introduction

The saw debinding machine is designed to remove short fibers (fluff) from the surface of cotton seeds at cotton processing plants and oil and fat factories.

The machine's primary function is to feed cottonseeds into the delinter chamber, where they are processed by a rotating saw drum. As they pass through the separator ribs, the short fibers are separated from the seeds, effectively separating the seeds from the residual fibers.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. produces a wide range of saw delineators and can select the optimal equipment model in accordance with the customer's technological requirements and processing volumes.

Specifications

Model

Seed productivity (kg/h)

Saw diameter (mm)

Power (kW)

Dimensions (L×W×H) (mm)

Mass (kg)

MR-144D |

First cleaning: 3500–4500 Second: 1000–1500 Third: 750–1000 |

Φ320 |

24.35 |

2600×1880×2000 |

2500 |

MR-164M |

First cleaning: 3500–4500 |

Φ320 |

27.85 |

2650×1950×1970 |

1800 |

MR-164S |

First cleaning: 4000–4500 Second: 900–1100 Third: 900–1100 |

Φ320 |

54.95 |

2650×1950×2480 |

3500 |

MR-161 |

First cleaning: 4000–5500 Second: 1200–1500 Third: 950–1200 |

Φ320 |

31.35 + |

2560×1320×2000 |

3000 |

MR-178 |

First cleaning: 4000–5500 Second: 1300–1800 |

F406 |

31.35 + |

2970×1400×2040 |

4000 |

Note:

The specified productivity is achieved by processing standard-quality cotton seeds with a moisture content of no more than 10%, while the residual fluff content and the quality of short fiber comply with the standards.

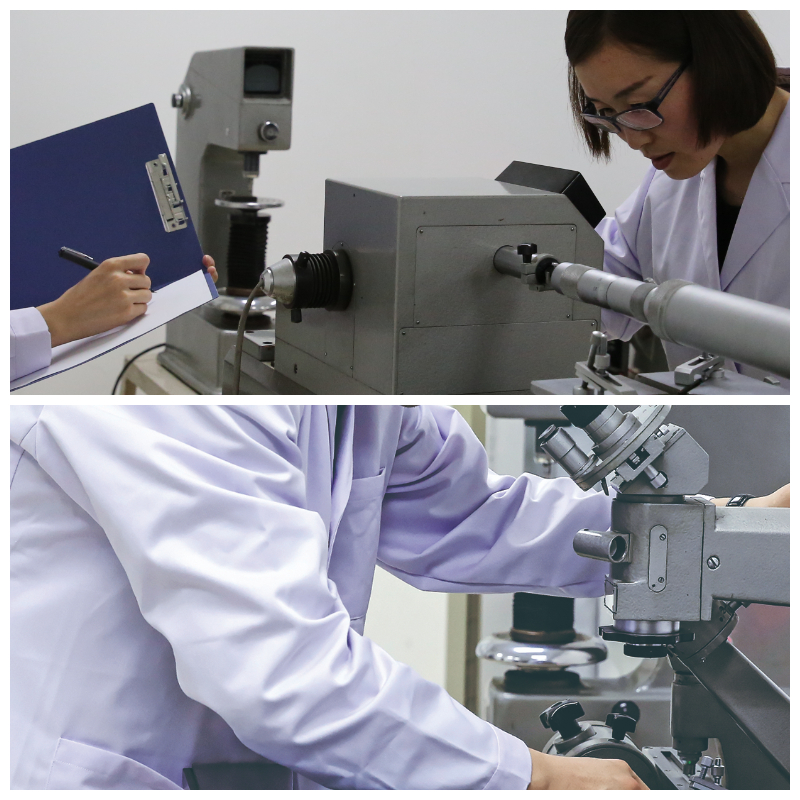

Product testing

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. conducts strict comprehensive testing on every product before shipment, including:

Visual inspection – checking that the color, shape, size and surface quality of the product meet the requirements.

Functional testing – checking the machine’s performance in operating mode, assessing its productivity and operational stability.

Safety tests – verification of compliance with electrical, mechanical and chemical safety standards.

Control of materials and components – chemical and spectral analysis, strength testing and processing accuracy.

Packaging and delivery

Packaging method: plastic film + moisture-resistant paper (or according to customer requirements).

Each vehicle is securely secured in a container for safe transportation to the destination port.

The entire container loading and sealing process is captured on photo and video, ensuring complete transparency and control.

The company partners with trusted shipping lines, and information about key delivery stages is updated in real time.

Company information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a joint-stock company owned by the Xindong Union of Supply and Marketing Cooperatives of Shandong Province.

Founded in 1946, it integrates R&D, precision manufacturing, marketing services and investment activities, providing comprehensive solutions and services for mechanized, intelligent and digital cotton processing equipment.

The company's products are exported to more than 30 countries, and for many years it has held a leading position in the domestic market, while its service network covers all major cotton-producing regions of the world.

Building on the development of cotton ginning technology, the company is promoting the modernization of the cotton industry, creating "smart factories," striving to become a global leader in the production of cotton processing equipment, actively developing smart agricultural machinery, and reaching the level of high-tech mechanical engineering.

The company's structure includes four technical centers and production bases - in Jinan (Shandong), Wujiaqiu (Xinjiang), Hailar (Inner Mongolia) and Montgomery (USA),

as well as three national high-tech enterprises and six provincial innovation platforms.

The company has been a technological leader in the industry for many years and is recognized as a high-tech enterprise in Shandong Province.

is the technical base of the National Program for the Promotion of Scientific and Technological Achievements and a participant in the National Program for Key Research and Development of the 13th Five-Year Plan.