Regenerative type raw cotton cleaning machine

The non-centralized design of the cleaning section ensures vibration cleaning of cotton.

Cleaning efficiency ≥50% while maintaining fiber integrity.

The recovery roller recovers lost cotton, reducing raw material losses.

Rational design of the machine: easy adjustment, simple maintenance.

Cylinder with 14-sided serrated nails using patented technology: high precision and stable operation.

CNC machined ball-and-socket nails minimize fiber damage and entrapment.

Protective cover with transparent elements, phosphating and powder coating: high adhesion, corrosion resistance and aesthetics.

Product Introduction

A regenerative seed cotton gin is a specialized piece of equipment designed for the simultaneous cleaning and re-selection of seed cotton. The machine removes impurities and recirculates (regenerates) the cotton seeds, ensuring high cleaning efficiency and reducing cotton loss.

The equipment is mainly used for cleaning machine-picked cotton, fast-picked cotton and traditionally hand-picked cotton.

The regenerative cotton cleaning machine manufactured by Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is characterized by high efficiency, reliability, a long service life, and gentle handling of the fibers. Its design allows for adjustable cleaning parameters depending on the cotton variety and quality requirements, ensuring optimal cleaning results.

Specifications

Model

Productivity (kg/h)

Power (kW)

Overall dimensions (L×W×H) (mm)

Mass (kg)

MALE-15 |

13000–15000 |

22 |

4740×3490×4360 |

7000 |

MALE-12 |

10000–12000 |

18.5 |

4290×3490×4360 |

6800 |

MIAZH-10 |

8000–10000 |

15 |

3740×3490×4360 |

6000 |

MEN-sh |

6000–7000 |

11 |

3090×3490×4360 |

4500 |

Note:

The stated productivity corresponds to the processing of standard grade raw cotton with a moisture content of no more than 7%, while the quality of the produced fiber meets established standards.

Product quality control

Functional testing: Verifies the correct operation of all equipment functions. Tests are conducted during machine operation or using specialized performance and functionality testing equipment.

Safety testing: Checks that products comply with applicable standards and regulations, including electrical, mechanical and chemical safety.

Packaging inspection: the integrity of the packaging, the clarity of the markings, and the compliance of the packaging materials with established requirements are checked, ensuring the safety of the product during transportation and storage.

Checking markings and instructions: The accuracy, completeness and legibility of markings and operating documentation are checked, as well as their compliance with current requirements and standards.

Packaging and delivery

Each vehicle is securely fastened and secured within the container to ensure safe delivery to the destination port.

The entire process of loading and sealing the container is recorded by photo or video, making it completely transparent and controllable.

Delivery is carried out in cooperation with reliable shipping companies; key stages of the journey are updated in real time.

Company information

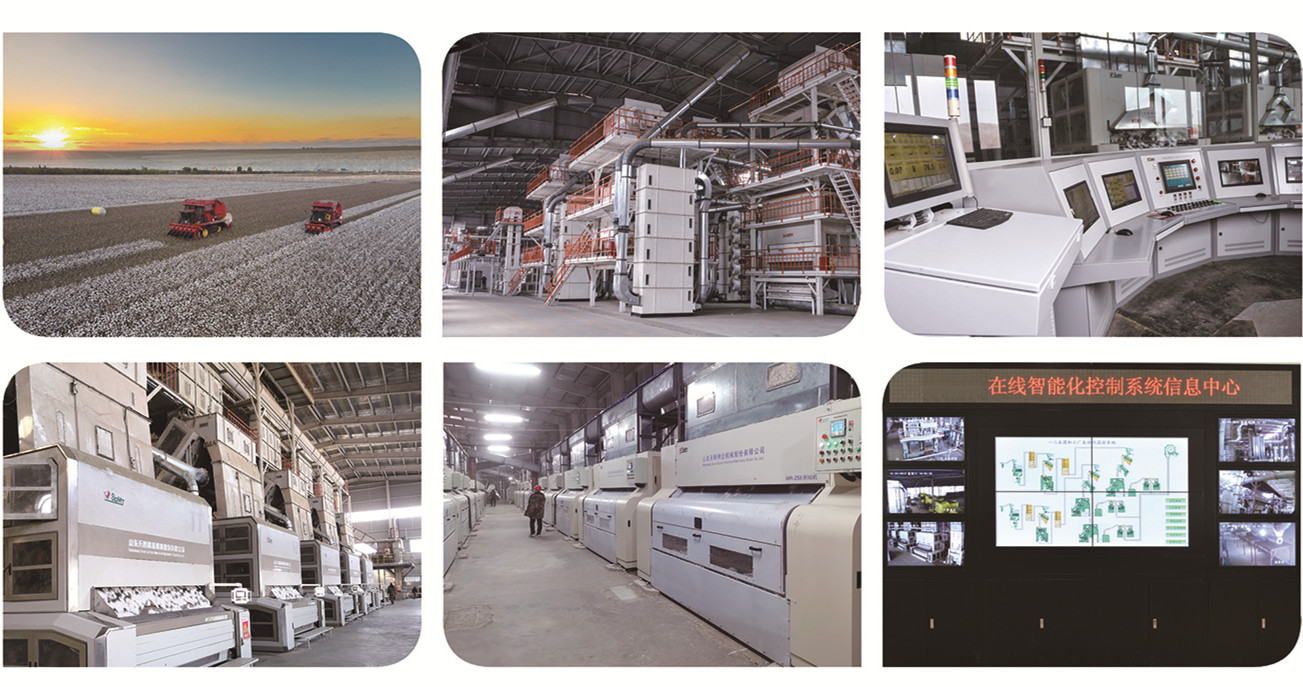

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a joint-stock company belonging to the Xindong Supply and Marketing Cooperative System. Founded in 1946, the company integrates research and development, precision manufacturing, marketing services, and investment, providing comprehensive solutions and services for mechanized, intelligent, and information-based cotton processing equipment.

The company's products are exported to over 30 countries worldwide, and its domestic market share has consistently held a leading position for many years. Its sales and service network covers all major global cotton-producing regions.

Based on the production of cotton ginning equipment, the company actively promotes the modernization and digitalization of the cotton industry, creates a new generation of "smart factories", strives to create a global brand in the field of cotton machinery, and expands its activities in the field of intelligent agricultural machinery and high-tech mechanical engineering.

The company has four technology centers and production bases in Jinan (Shandong Province), Wujiaqu (Xinjiang), Hailar (Inner Mongolia), and Montgomery (USA). It operates three national high-tech enterprises and six provincial innovation platforms.

For many years, the company has been a leader in technological development in the industry.

Shandong Swan is a high-tech enterprise in Shandong Province, a technical participant in the National Program for the Promotion of Scientific and Technological Achievements, and an executor of the National R&D Program "13th Five-Year Plan".