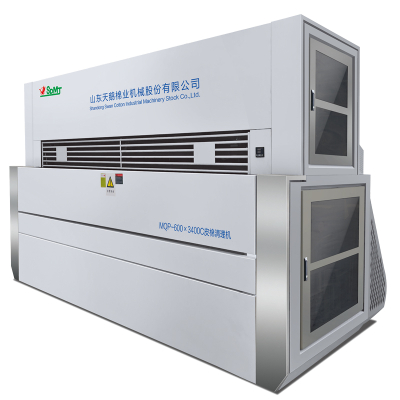

Cotton bale press

Modular pin design: high rigidity, easy installation, stability and reliability.

Solid cotton box and suction casing: prevent fiber expansion and scattering, high efficiency.

Patented weighted hook design with low failure rate.

Hydraulic box lift with step-by-step control: shock reduction, automatic locking, safety and reliability.

Recirculation cooling and filtration of the hydraulic system; Parker seals (USA) for long service life.

Flexible hydraulic control of the pusher and box rotation: minimal impacts, stable speed.

Cylinder and tamper induction with infinite positioning; PLC ensures precise control, automatic fault display, and uniform bale weight.

1. Product Introduction

A cotton baler is a device used to compress and package fiber (lint). The main function of a baling press is to compress loose fiber into a compact package for easy storage and transportation.

?️ Technical Specifications (Main Parameters)

1400*530*700227±10

Main Parameters |

20 Keep/ch |

25 Keep/ch |

30 Keep/ch |

40 Keep/ch |

Designed Output |

20 kip/h (4540 kg) |

25 kip/h (5675 kg) |

30 kip/h (6810 kg) |

40 kip/h (9080 kg) |

Nominal Working Pressure |

4000 kN |

4000 kN |

4000 kN |

4000 kN |

Bale Dimensions |

1400*530*700 |

1400*530*700 |

1400*530*700 |

|

Bale Weight |

227±10 |

227±10 |

227±10 |

|

Compression Height |

485-508 |

485-508 |

485-508 |

485-508 |

Power |

85 KW |

115 KW |

123 KW |

153 KW |

Machine Weight |

45000 KG |

45000 KG |

45000 KG |

45000 KG |

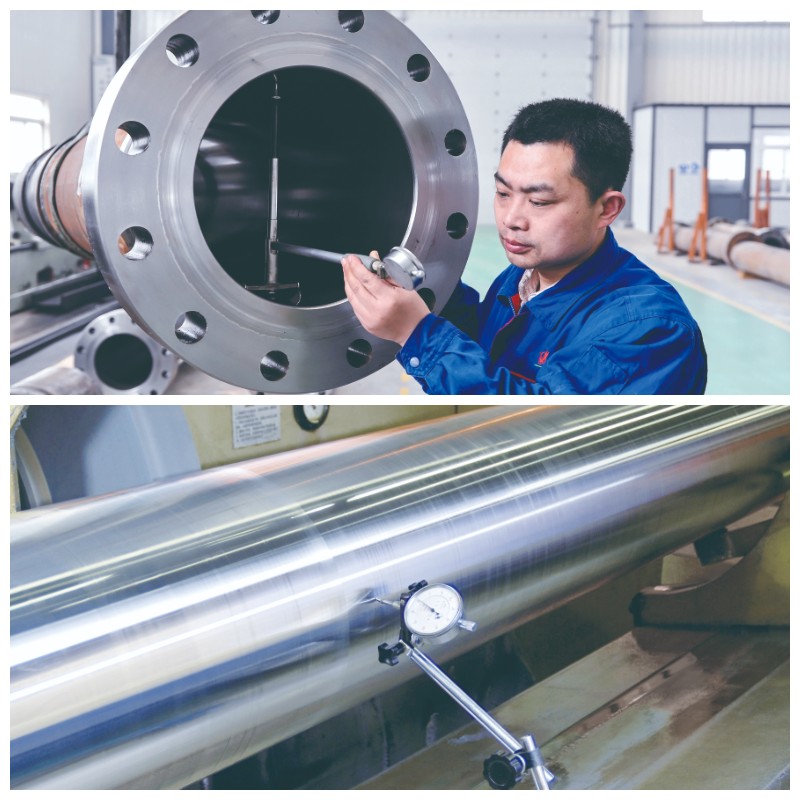

? Product Inspection

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. carries out strict comprehensive testing for each factory product, which includes the following:

(1). Appearance inspection:

Checking whether the product's appearance meets requirements, including color, shape, size, surface cleanliness, etc. This can be done by visual inspection or using auxiliary instruments (e.g. microscopes, measuring instruments).

(2). Functional Testing:

Verifying the correct operation of a product's functions. This can be accomplished by operating the product for functional testing or using specialized test equipment to verify the product's performance and functionality.

(3). Label and instruction manual inspection:

Verification of the accuracy, clarity, completeness of product labelling and operating instructions, as well as their compliance with applicable regulations and standards.

(4). Safety testing:

Verifying product compliance with relevant safety standards and regulatory requirements. This may include testing for electrical safety, mechanical safety, chemical safety, and more.

? Packaging and Delivery

(1) Each vehicle is securely fastened and reinforced in the container to ensure safe arrival at the destination port.

(2) The entire process of product loading and container sealing is recorded by photo or video, making the entire process visible and controllable.

(3). Cooperation with a reliable shipping company, key time points (stages) are updated in real time.

? Company Information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a joint stock company owned by Shandong Supply and Marketing Cooperatives.

Based on cotton machinery industry as the core business, the company focuses on promoting the transformation and upgrading of the cotton industry, creating a new era of smart factories, forming the world's leading brand of cotton machinery industry, actively expanding into the intelligent agricultural machinery industry, and fully entering the high-tech equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. has four technical centers and production bases in Jinan (Shandong), Wujiaqu (Xinjiang), Hailar (Inner Mongolia) and Montgomery (USA), as well as three national high-tech enterprises and six provincial innovation platforms, leading the technological progress of the industry for many years. It is a high-tech enterprise in Shandong Province, the technical support unit of the "National Key Program for the Promotion of Scientific and Technological Achievement" and the implementer of the "13th Five-Year Plan" of the National Key Research and Development Program.

For more video information, please visit our YouTube channel:

https://www.youtube.com/@SwancottonMachinery