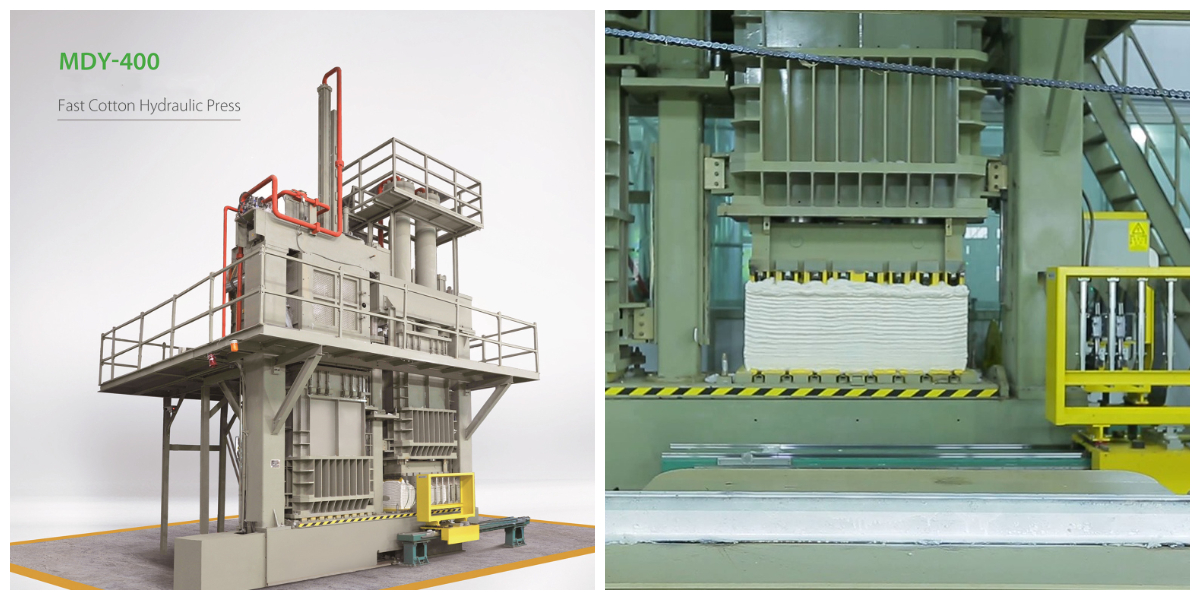

Cotton baling press

The modular design with pin positioning ensures high rigidity, ease of installation, stability and reliability.

The one-piece pressing chamber and suction casing prevent deformation and scattering of fibers, ensuring high productivity.

The patented weighted hook system reduces failure rates and ensures consistent operation.

Hydraulic camera lift with step-by-step control reduces shock, provides automatic locking and safety.

The recirculation cooling and filtration system with Parker (USA) seals ensures stable operation and durability.

Flexible hydraulic pusher control and hydraulic motor with proportional valve for chamber rotation ensure stability and speed.

Infinite adjustment of the piston position and the compaction mechanism with PLC allows for precise control, automatic fault indication and uniform bale weight.

Product Introduction

A cotton bale press machine is a modern piece of equipment used for pressing and packaging cotton fiber (lint) and similar materials. These baling presses are widely used in cotton ginning and agricultural enterprises to compact the raw material into compact bales.

The primary function of a baling press is to compress loose material into dense, neat bales, significantly facilitating their storage, transportation, and subsequent processing. Compaction reduces the fiber volume, optimizes warehouse space utilization, and makes logistics simpler and more cost-effective.

The operating principle and design of the equipment are similar to a hay baler, but it is adapted to the characteristics of cotton fiber, ensuring uniform compaction, stable bale weight, and high productivity.

The cotton press, developed and manufactured by Shandong Swan Cotton Industrial Machinery Co., Ltd., fully meets the requirements of cotton gins both in China and abroad. The equipment features high productivity and stable operation, and is widely used in key cotton-growing regions such as Xinjiang (China), Brazil, Central Asia, and other countries with developed cotton production.

Specifications

Parameter

A unit of measurement

Meaning

Productivity (bales/hour) |

— |

20 (4540 kg) / 25 (5675 kg) / 30 (6810 kg) / 40 (9080 kg) |

Nominal working pressure |

kN |

4000 |

Bale size |

mm |

1400 × 530 × 700 |

Bale weight |

kg |

227 ±10 |

Baling height |

mm |

485–508 |

Power |

kW |

Pumping / 115 / 123 / 153 |

Machine weight |

kg |

45000 |

Product Inspection

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. conducts strict comprehensive testing on every product before shipment, including:

External inspection – control of color, shape, size and surface quality.

Functional testing – checking the correct operation of the equipment and all functions.

Checking the markings and instructions – compliance of the documentation with requirements and standards.

Safety testing – compliance with electrical, mechanical and chemical safety regulations.

Packaging and delivery

Each vehicle is securely secured in a container to ensure safe delivery.

The entire process of loading and sealing the container is recorded in photographs and videos.

Collaboration with trusted shipping companies allows us to monitor key stages of transportation in real time.

Company information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a joint-stock company belonging to the Shandong Provincial Supply and Marketing Cooperative System. Founded in 1946, it integrates research and development, precision manufacturing, marketing services, and capital investment.

The company is a leader in cotton ginning equipment production in China, supplying products to over 30 countries worldwide. Its core business is developing smart factories and automated solutions for the cotton industry, as well as expanding into intelligent agricultural machinery.

The company's production and technical bases are located in Jinan (Shandong), Wujiaqiu (Xinjiang), Hailar (Inner Mongolia), and Montgomery (USA). The company has four technical centers, three national high-tech enterprises, and six provincial innovation platforms.

? For more information and videos, visit our YouTube channel:

?https://www.youtube.com/@SwancottonMachinery