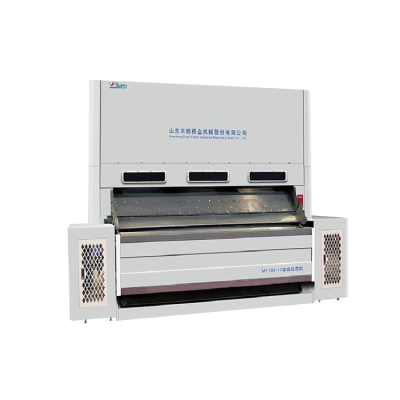

Cotton cleaner

Patented product for high efficiency businesses, for machine picked cotton only.

New feed structure: efficient cleaning, uniform feed, no dust scattering.

The new working box ensures high productivity and good quality.

Imported saw blades (USA) – high performance, long service life, high-quality cleaning.

The new adjustment system allows for free control of the percentage of fibre on the seeds.

Intelligent control ensures ≥98% safe operation.

Simple and rational design: stable operation, convenient maintenance, modern materials and technologies.

? Cotton Saw Gin MY199-16

Product Introduction

The MY199-16 cotton saw gin is specially designed for separating cotton fiber from cotton seeds and cleaning cotton seeds.

⚙️ Technical Specifications

Parameter |

Model |

Model |

Mi199-16 |

Designed output |

2000-3000 kg/h |

Equipped power |

107.25kW |

Lint ginning quality |

Meets or exceeds the national standard for ginned cotton |

Noise level |

90 dB |

Number of saw blades (Pieces of saws) |

199 pcs. |

Diameter of saw blades |

406 mm |

Saw spacing |

16 mm |

Diameter of brush cylinder |

450mm |

Overall dimensions (W*D*H) |

3676 * 4560 * 3558.5mm |

Machine weight |

11,000 kg |

? Packaging and Delivery

We provide individual (customized) packaging method for customers.

(1). Each machine is securely secured and reinforced in a container to ensure safe delivery to its destination port.

(2) The entire process of loading the product and sealing the container is recorded by photo or video, making the entire process visible and controllable.

(3). Cooperation with a reliable shipping company, key time points (stages) are updated in real time.

? Product Inspection

(1) Monitoring the external condition and performance

(Visual & Functional Check):

The product is checked for compliance with the requirements for appearance, including color, shape, size and surface cleanliness. Control is carried out by visual inspection or using auxiliary measuring and optical means. At the same time, an initial assessment of the product's performance is performed through practical use, functional testing, or the use of specialized test equipment to confirm performance characteristics.

(2). Functional tests

(Functional Performance Test):

A detailed check of the correct functioning of the product is carried out through operational tests, targeted functional tests or the use of specialized test facilities to evaluate performance and functional parameters.

(3). Security Compliance Check

(Safety Compliance Testing):

The product is tested for compliance with current safety standards and regulations, including electrical, mechanical and chemical safety testing.

(4) Control of packaging and labeling

(Packaging and Labeling Inspection):

The integrity and strength of the packaging, the legibility and accuracy of the markings, and the compliance of the packaging materials with established requirements are assessed. This stage ensures the protection of the product during storage and transportation and allows for its correct identification.