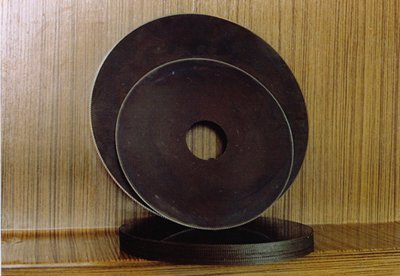

Saw blades for gins

Made from imported material from the USA, which has high strength, excellent toughness and long service life.

Uniform thickness and smooth surface ensure high fiber quality and reduce knot formation (neps).

The patented variable tooth geometry design, adapted to a variety of processing conditions, ensures high versatility.

The φ406 diameter saw is manufactured by Shandong Swan USA, Inc. and comes with original imported components to ensure quality.

Swan Cotton Ginning and Dehairing Saws are made from imported sheet metal sourced from the USA, which ensures longer service life and superior product quality. We use the world's leading automatic saw blade manufacturing equipment to ensure high precision processing and consistent product quality to meet a variety of customer requirements. High productivity allows for timely delivery of orders. The production process is safe and environmentally friendly and does not harm the environment.

1.

| Parameter | Cotton gin saws 406 | Cotton gin saws 320 | Dehairing saws 320 |

|---|---|---|---|

| Number of teeth | 330 | 304 | — |

| Outer diameter, mm | 406 | 320 | 320 |

| Inner diameter, mm | 174,6 | 74,6 | 74,6 |

| Surface hardness (HRC) | 35 | 35 | 35 |

| Surface flatness, mm | 0,4 | 0,4 | 0,4 |

2. Packing method:

Waterproof paper + PE film or individual packaging as per buyer's requirement.

(1) The transportation method is flexible and can be changed according to customer's needs.

(2) The packaging materials are strong and durable, suitable for long-distance international sea and land transportation.

(3) The packaging is customer-oriented and can be customized.

3. Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. conducts strict comprehensive inspection of every product before it leaves the factory. Key inspections include:

(1) External inspection: the product's appearance is checked to ensure it meets the requirements for color, shape, size, surface quality, etc. The inspection can be carried out visually or using auxiliary instruments (e.g. microscopes, measuring instruments).

(2) Dimension and weight verification: The dimensions and weight of the product are measured and compared with the design specifications to confirm compliance. Measuring instruments, scales, and other equipment are used for this purpose.

(3) Testing of materials and components: The conformity of the materials and components used with the established requirements is checked using chemical analysis, spectral analysis, tensile testing and other methods.

(4) Checking labelling and operating instructions: The accuracy, clarity and completeness of labels and user manuals are checked, as well as their compliance with current regulations and standards.