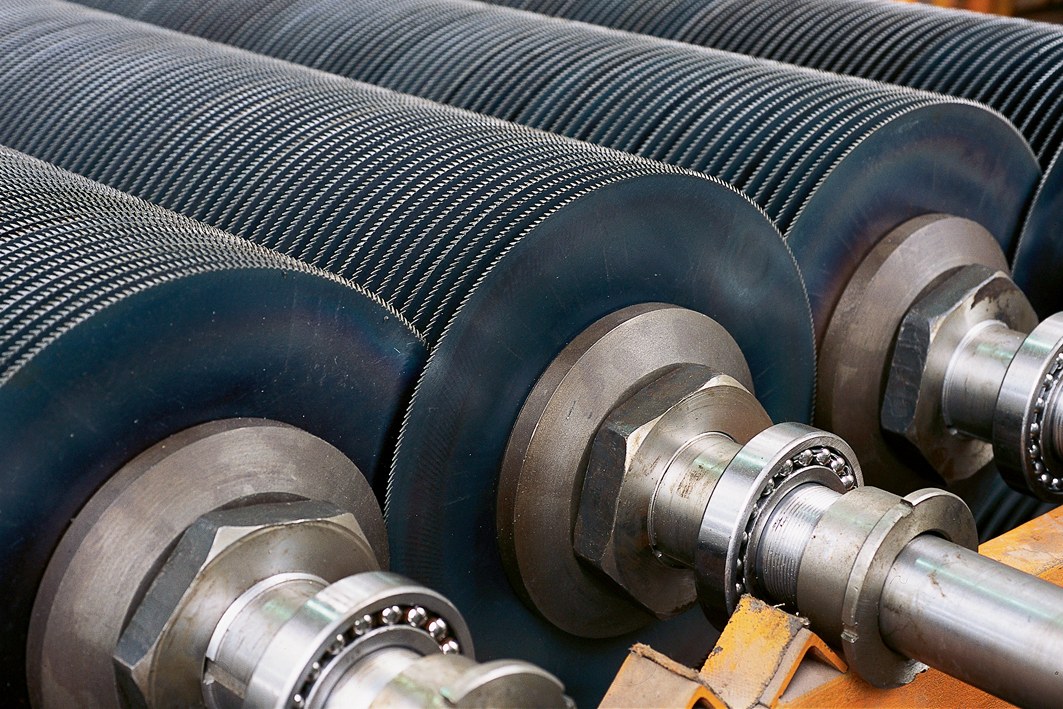

Cotton gin pin cylinder

1. Using high quality special steel to ensure long service life.

2. Upper teeth hardening, grinding, high wear resistance and strong anti-jamming ability.

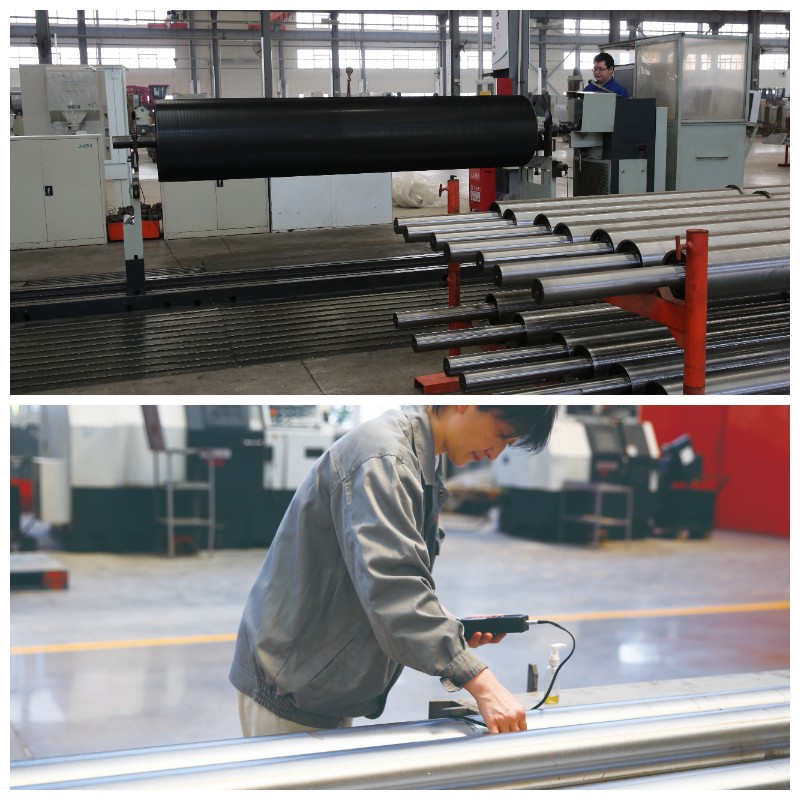

3. Manufactured on a professional assembly line, the precise shape ensures a tight fit (pressing) of the saw to the round roller.

4Adopting advanced international laser processing technology, high precision, no deviation.

?The Role of Spike Cylinder of Cotton Ginning Machine

The spiked cylinder of the cotton gin plays a key role in separating and aligning the fiber bundles. During operation of the equipment, the spiked cylinder on the carding rollers comes into contact with the fiber bundles and effectively separates them through the carding action, resulting in a smoother and more uniform distribution. In addition, the cotton gin's spiked cylinder helps remove contaminants and residue from the fiber bundles, thereby improving the overall quality and appearance of the cotton.

? Packaging and Delivery

1. Flexibility and Variability of Transportation

The transportation method is flexible and changeable, and different modes of transportation can be selected according to customers' needs.

2. Quality of Packaging Material

The packaging material is strong and durable, capable of withstanding long-distance international transportation.

3. Individual Approach

Customer focus, possibility of individual packaging.

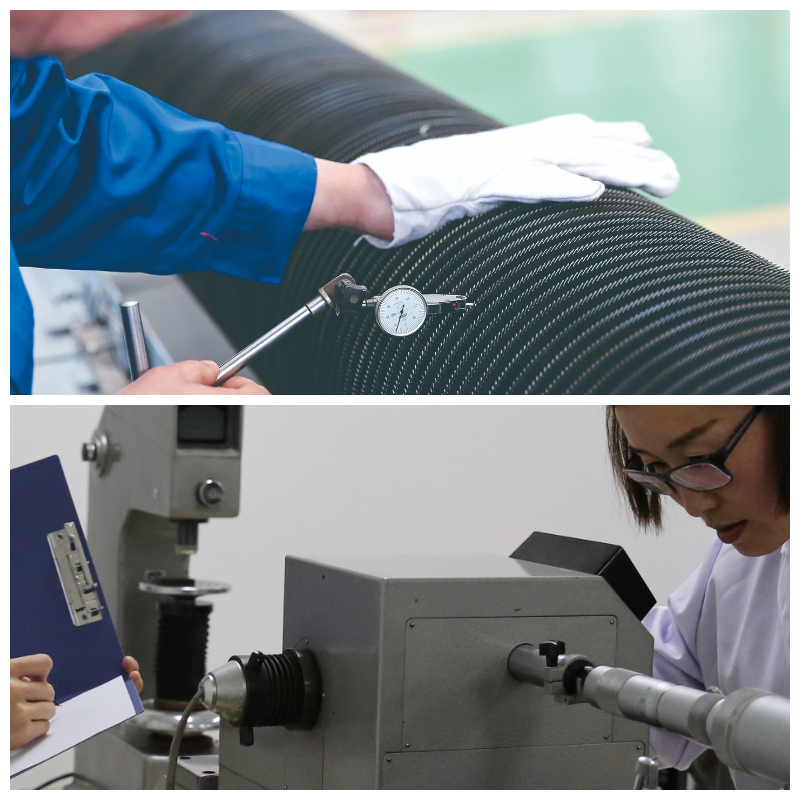

? Product Inspection

We implement strict, multi-stage quality control on all products manufactured by the company. Each item undergoes a comprehensive inspection, including the following key procedures.

Visual Appearance Check:

The product's conformity to established requirements is assessed for appearance, including color, geometry, dimensions, and surface condition. The inspection is performed visually or using auxiliary means, such as measuring and optical equipment.Functional Performance Test:

Correct operation of the product is verified by hands-on operation, functional testing, or the use of specialized test facilities to evaluate performance and performance.Safety Compliance Testing:

We monitor product compliance with current safety regulations and standards, including electrical, mechanical and chemical safety checks.Packaging and Labeling Inspection:

The strength and integrity of the packaging, the legibility and accuracy of the markings, and the compliance of the packaging materials with established requirements are checked. This ensures the protection of the product during storage and transportation and allows for its correct identification.